BUY MORE, SAVE MORE ON

MITEE-BITE

Buy 5 Packs And Get 5% Off

Buy 10 Packs And Get 10% Off

*does not apply to low-profile spring clamps

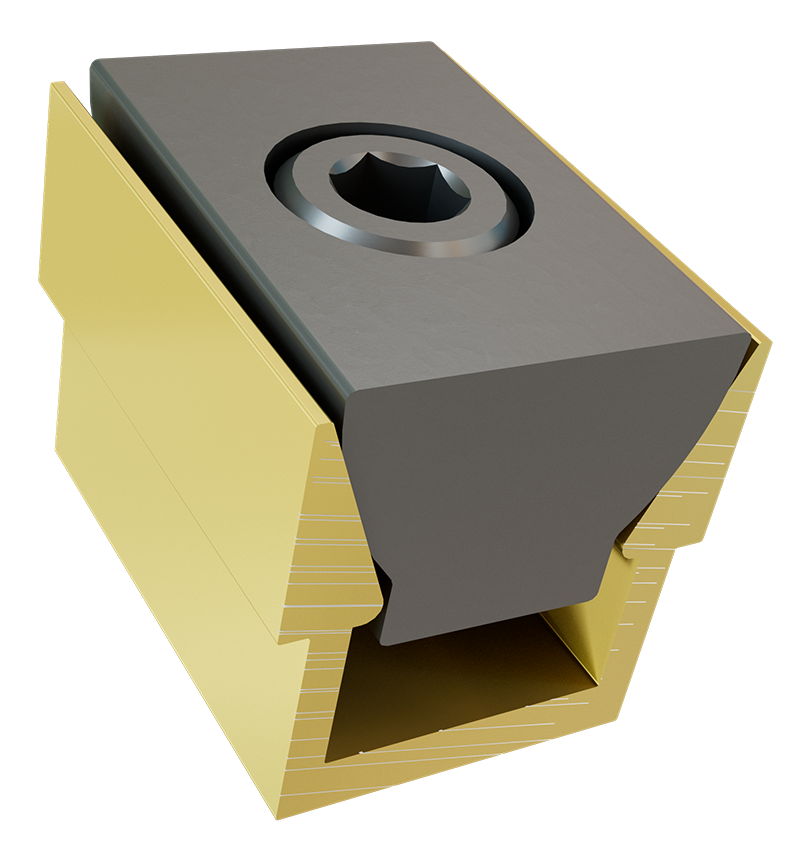

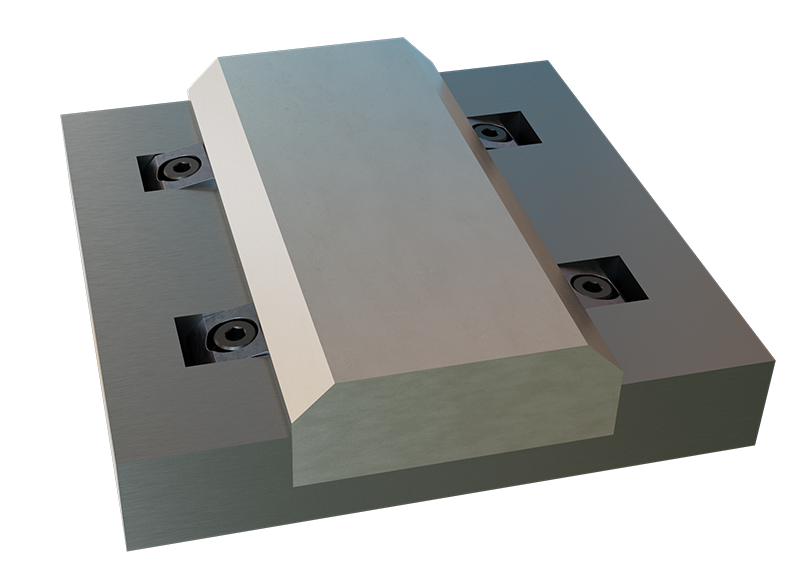

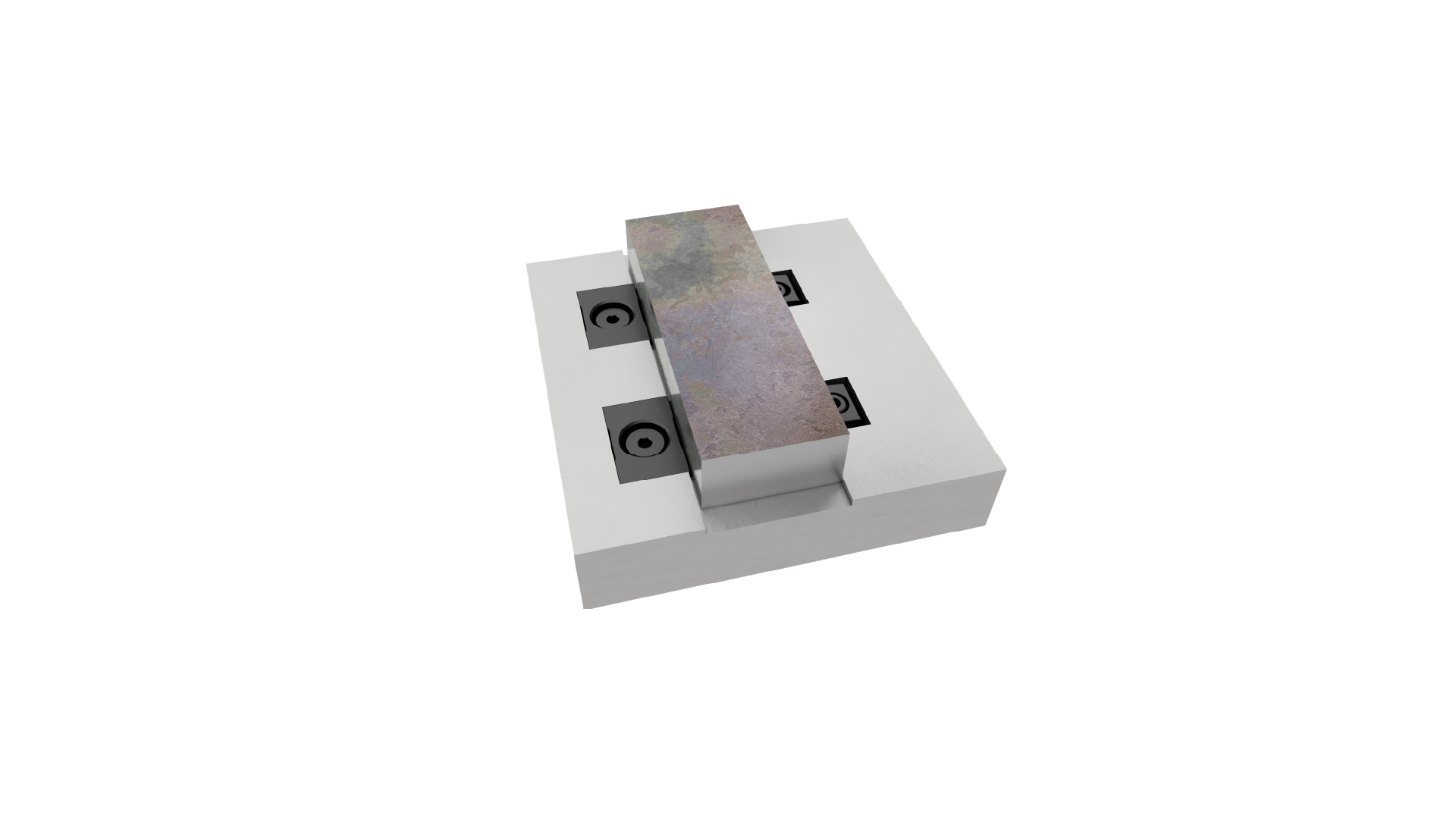

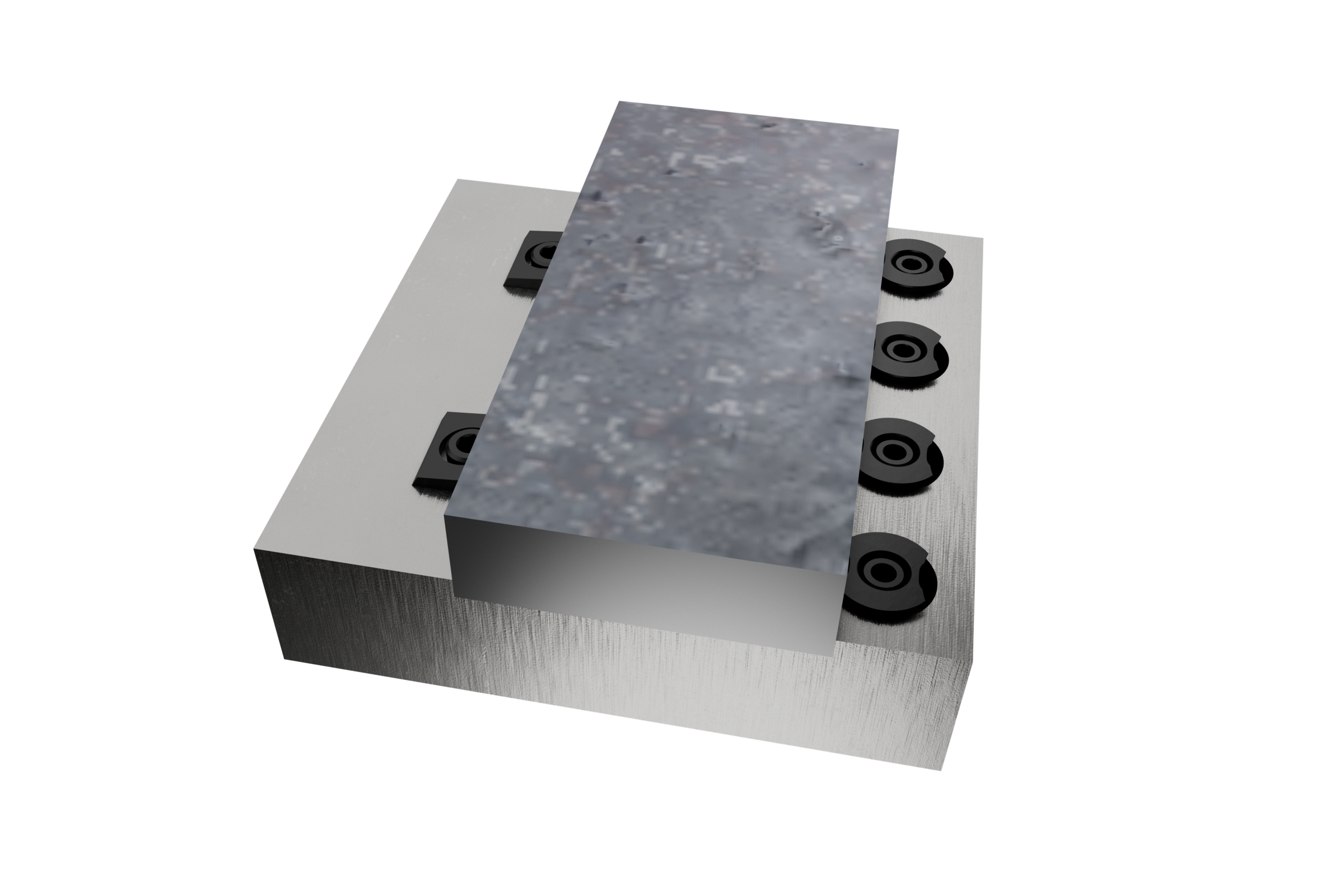

Uniforce® Clamps (Dual-Part Clamping)

Uniforce® clamps combine a steel wedge and aluminum channel designed to clamp two parts with equal force quickly. Machinable clamps are also available with or without a locking plate, allowing the clamping jaws to be machined to fit the workpiece profile.

ID Xpansion Clamps

ID Xpansion Clamps allow parts to be clamped by an inner diameter. The machinable clamp allows for custom sizes and shapes of ID features to be secured. The clamp is mounted to a fixture using tapped holes, and a center screw is tightened to apply outward force, securing the ID of a workpiece.

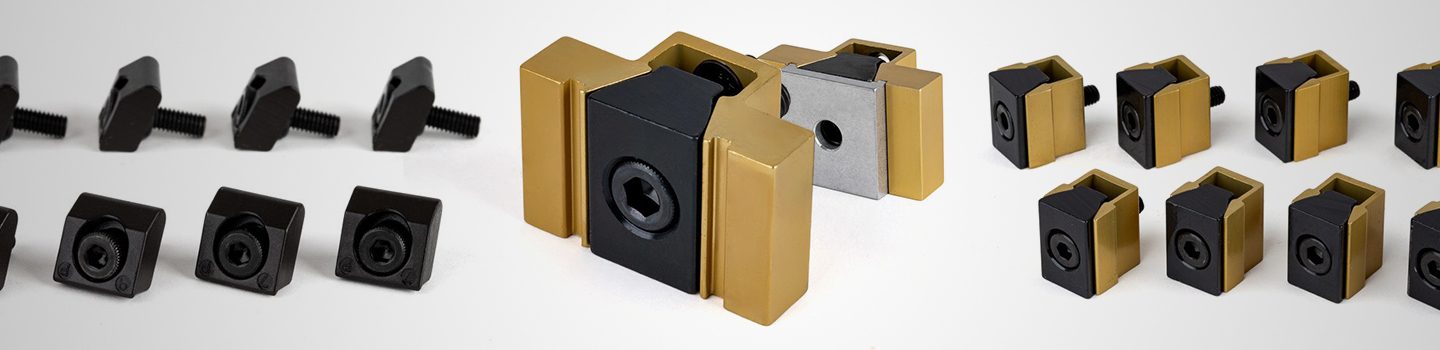

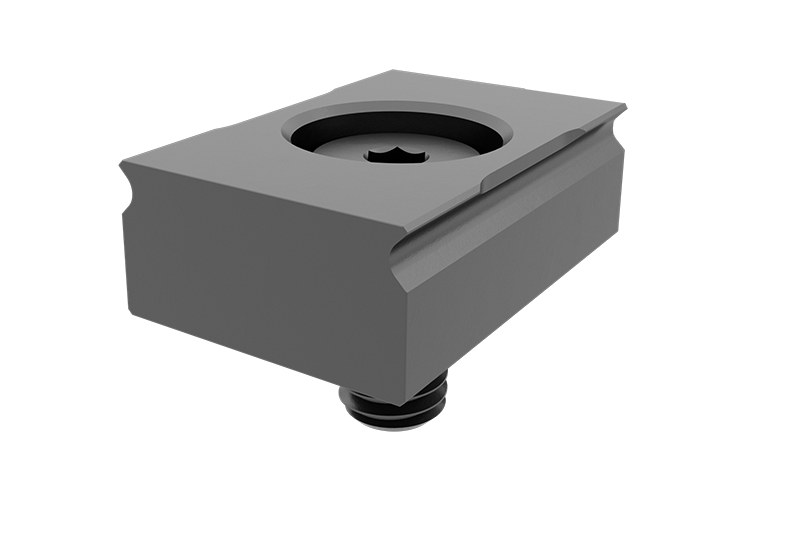

Pitbull® Clamps (Single-Part Clamping)

Pitbull® low-profile steel clamps are designed to clamp a single part with maximum force. High vertical and horizontal clamping forces are generated by the unique angled wedge clamping action. Machinable clamps are also available, complete with set-up pins to aid in the machining of the workpiece profile.

TalonGrip™ Clamps

TalonGrip™ uses a serrated edge that creates more holding force than a smooth fixture wall. Use these on the fixed side of a fixture along with Pitbull or UniForce clamps.

Low-Profile Spring Clamps & Rails

Low-Profile Spring Clamps are a combination of a steel wedge and spring-loaded base designed to quickly clamp workpieces to fixture plates. Capable of clamping one or two workpieces with one clamp. Offered in flat, hole, and serrated edge types.

VersaGrip™ Clamps

VersaGrip™ uses a serrated edge that creates more holding force than a smooth fixture wall. Use these on the fixed side of a fixture along with Pitbull or UniForce clamps. Can be used to hold odd shaped parts without custom fixturing.

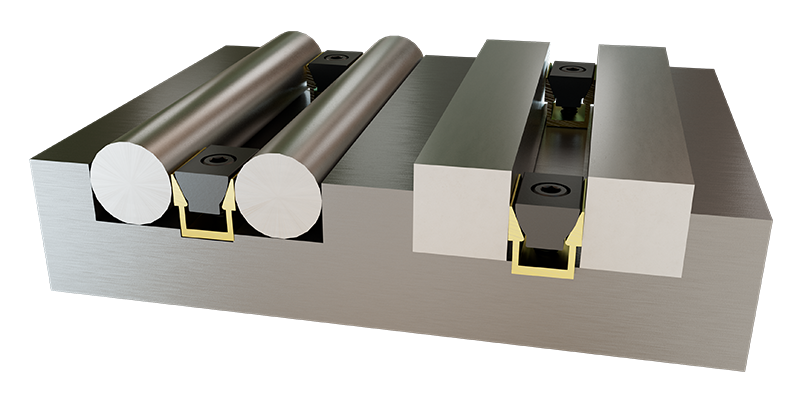

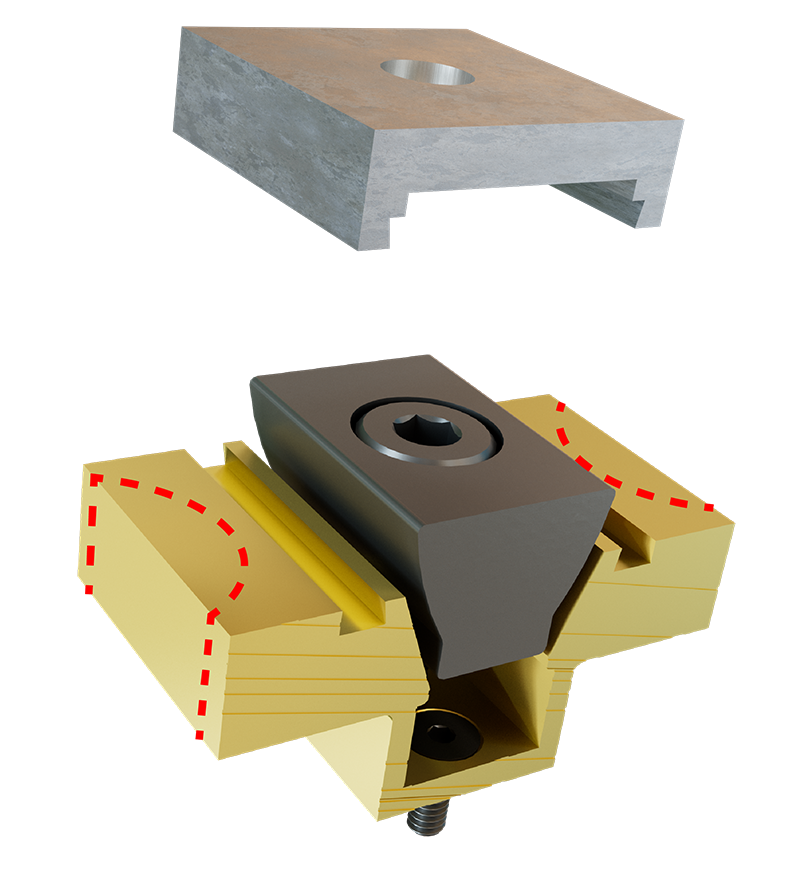

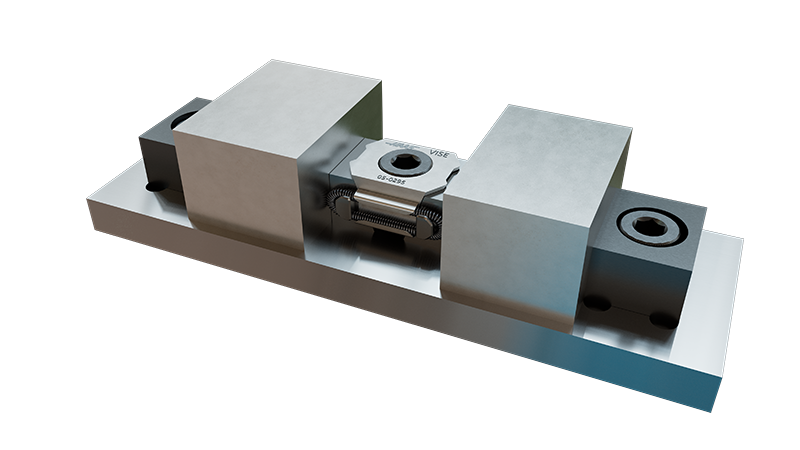

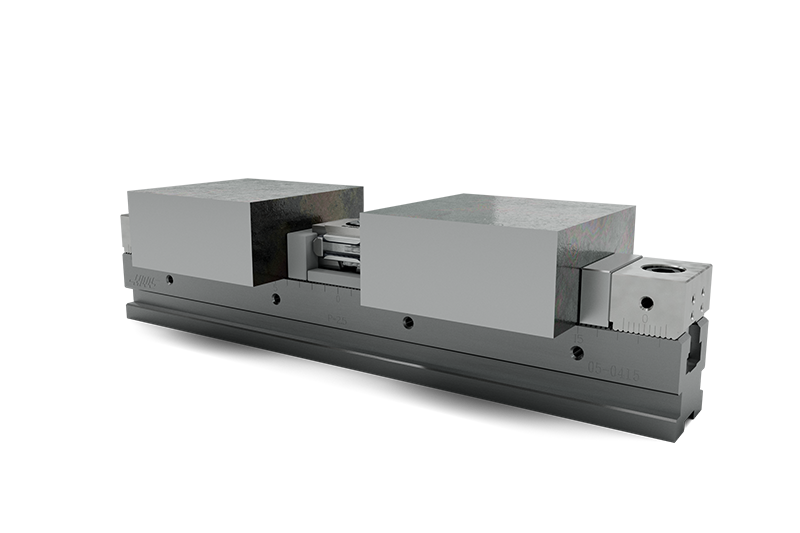

Uniforce® Clamps

____________________________

Uniforce® clamps are a combination of a steel wedge and aluminum channel designed to quickly clamp two parts with equal force.

Machinable version clamps are also available and can be purchased with or without locking plates. The locking plate retains the machinable jaws in a rigid, geometrically square position, to allow for machining of the workpiece profile. Once the jaws have been machined the locking plate is removed before clamping the workpiece.

Features

- Usable on flat or round workpieces

- Milled pocket not required to install clamps

- Clamp two parts equally using one clamp

- Aluminum clamping surface less likely to leave marks on the workpiece

What's Included

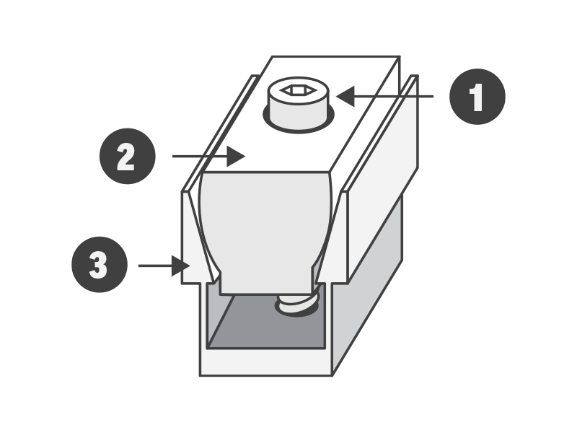

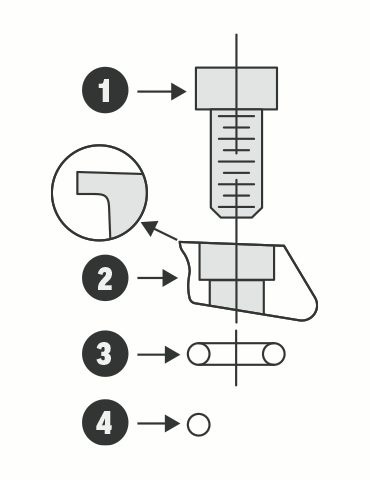

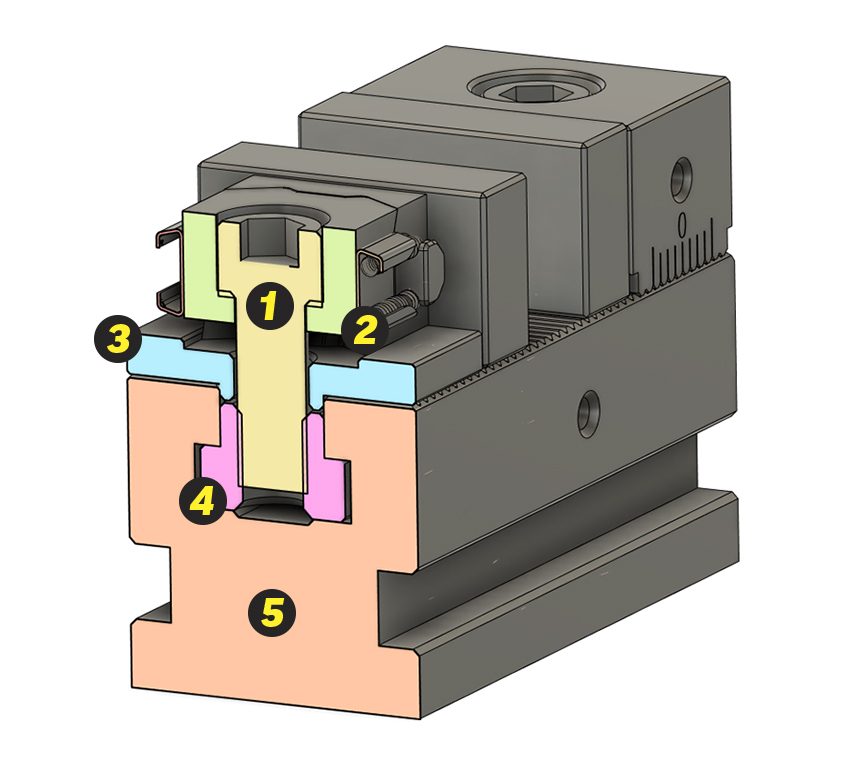

Non-Machinable

1. Cap Screw | 2. Steel Wedge | 3. Aluminum Channel (7075-T6)

Machinable

1. Cap Screw | 2. Steel Wedge | 3. Machinable Aluminum Jaw (7075-T6)

| 4. Locking Plate (Optional) | 5. Mounting Screws

How Can I Fixture Parts Using Uniforce® Clamps?

These can quickly clamp multiple parts to help increase production. Check out below for examples of these clamps in use.

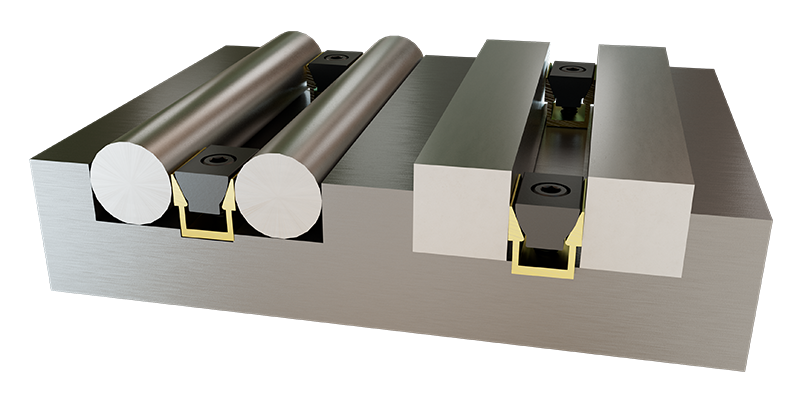

Square Or Round Parts

Using the non-machinable Uniforce® clamps, round or square stock can be held by having the clamp act as a wedge, clamping the workpiece up against a machined part stop.

Profile Parts

Using the machinable clamps, profile parts can be clamped by machining the profile of the workpiece into both sides of the clamp and clamping the workpiece up against a machined part stop.

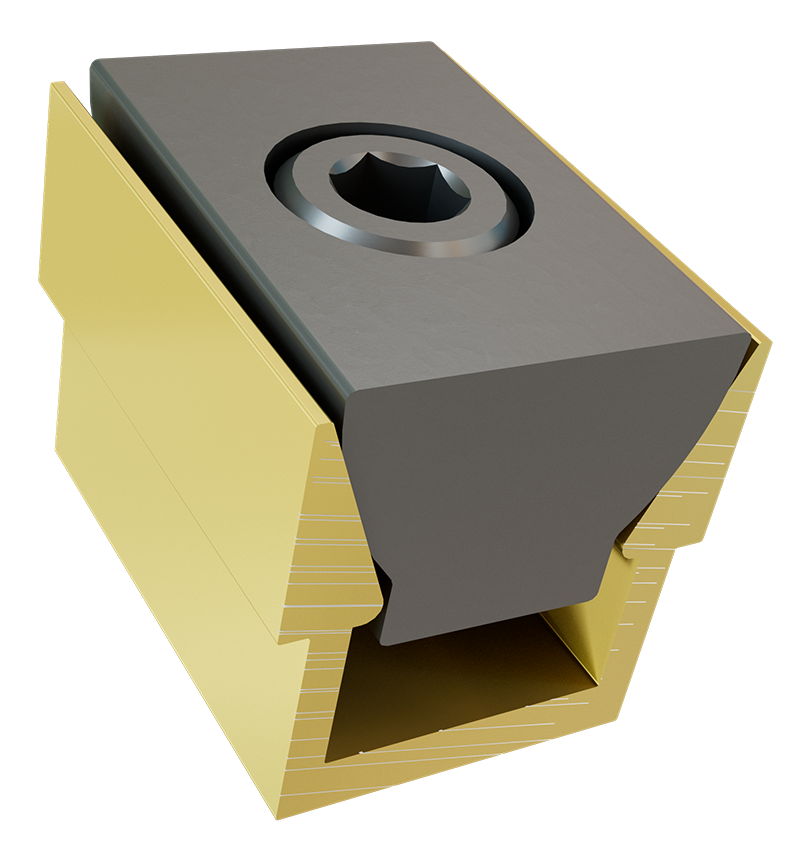

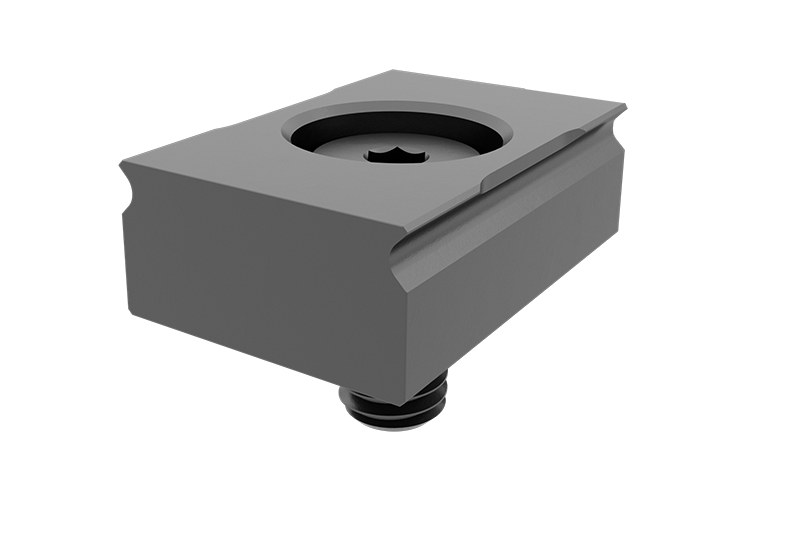

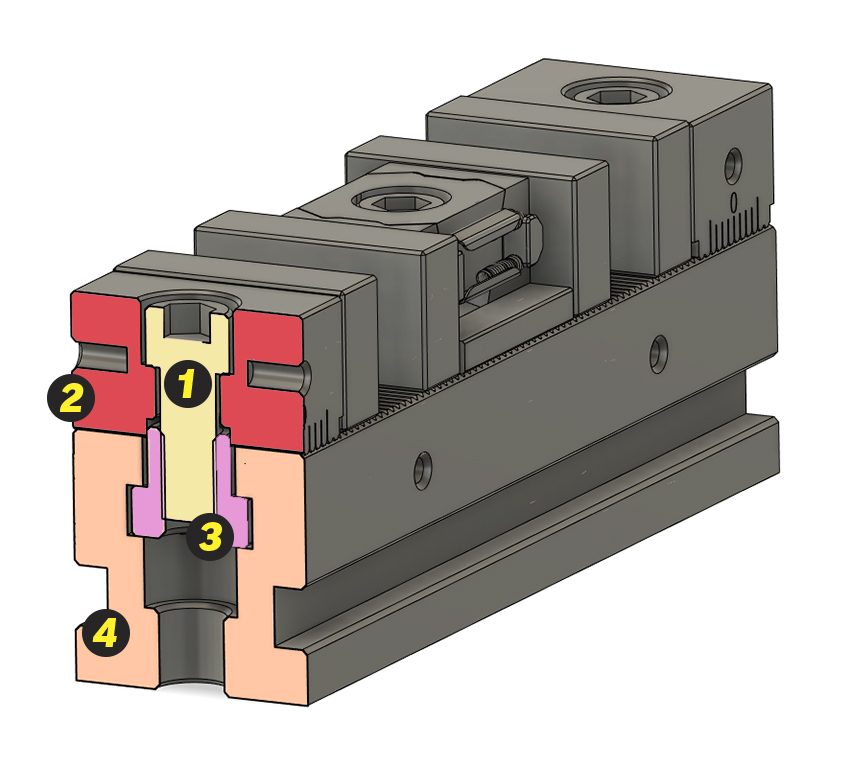

Pitbull® Clamps

____________________________

Pitbull® low-profile steel clamps bite and pull down on the workpiece to create high vertical and horizontal clamping forces. Machinable clamps are also available, complete with set-up pins to aid in the machining of the workpiece profile.

Features

- Usable on flat or round workpieces

- Low profile clamp for maximum tool access

- Positive down force clamping

- Various sizes available

- Machinable versions are also available

Different Edges for Different Purposes

- Knife Edge is designed for biting and pushing down on workpieces to secure them for heavy material removal, best for first operations.

- Blunt Edge is designed for general-purpose machining and is less likely to leave marks on the workpiece; great for second operations.

- Machinable Edge is made of A2 tool steel heat treated to 43RC and can be machined to match the profile of a complex workpiece to increase clamping area; great for second operations and profile parts.

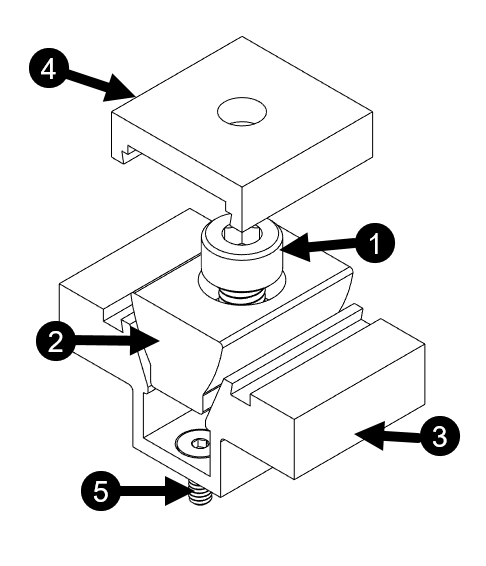

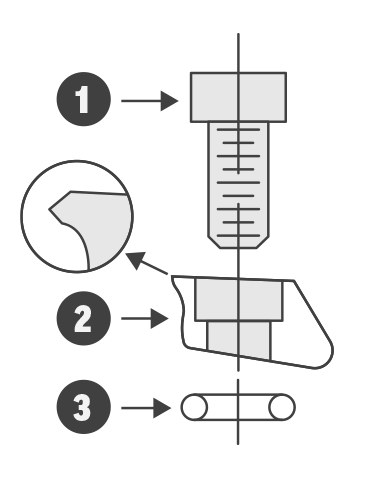

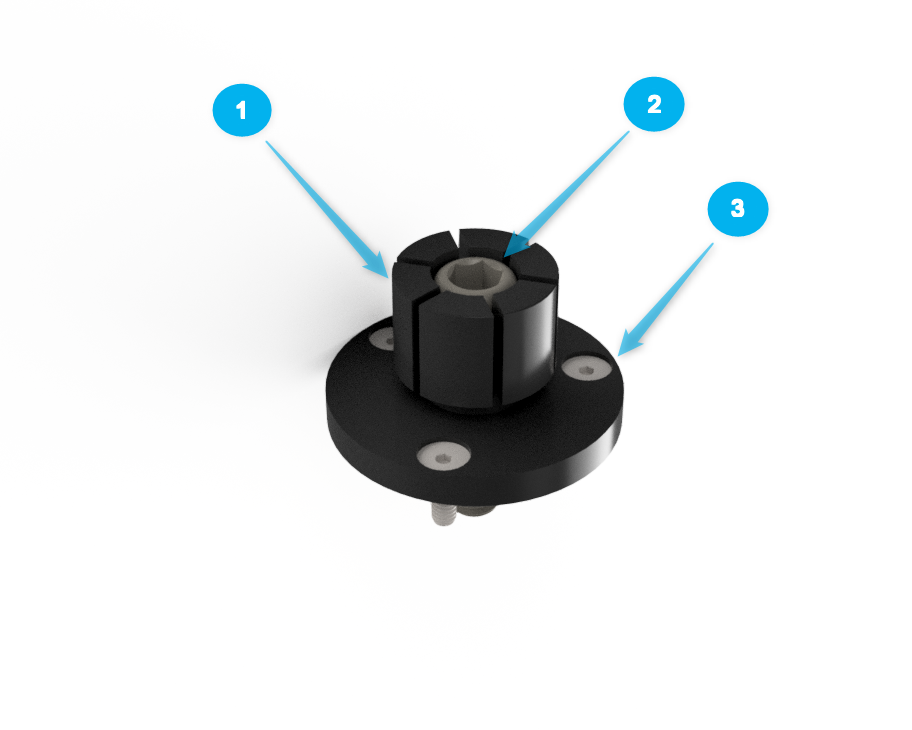

Knife Edge

1. Cap Screw | 2. Clamp | 3. O-Ring

Blunt Edge

1. Cap Screw | 2. Clamp | 3. O-Ring

Machinable Edge

1. Cap Screw | 2. Clamp | 3. O-Ring | 4. Machining Dowel Pin

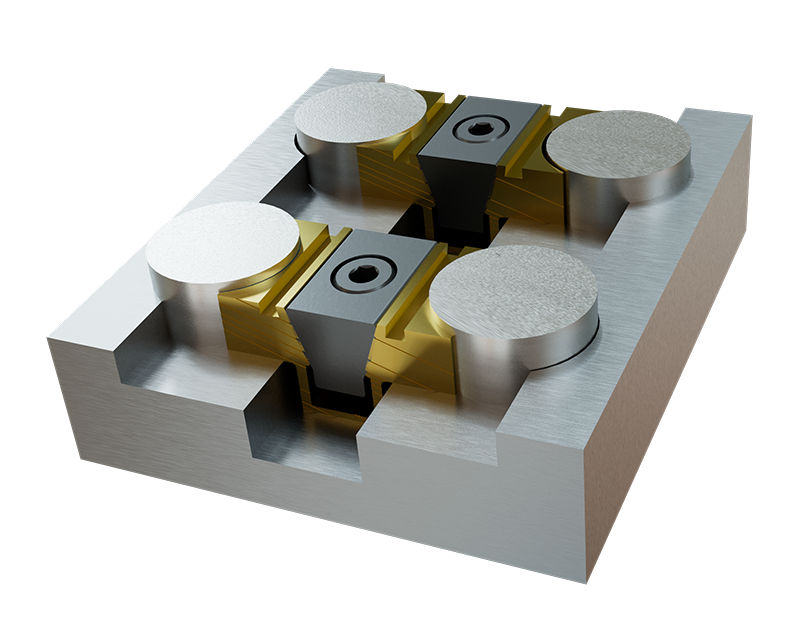

Application Examples

Clamp the workpiece with a single clamp or use multiple clamps on different sides. Check out below for some examples of how to use these clamps.

Example A:

Clamping a Part Against a Work Stop

Example B:

Clamping a Part on Multiple Sides

Example C:

Clamping Profile Parts on Multiple Sides

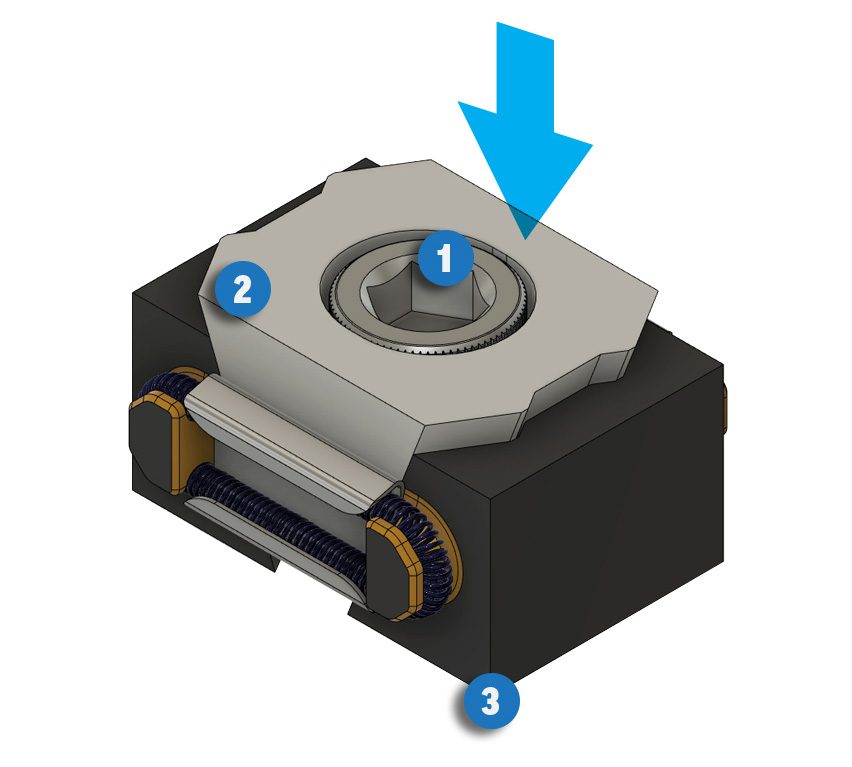

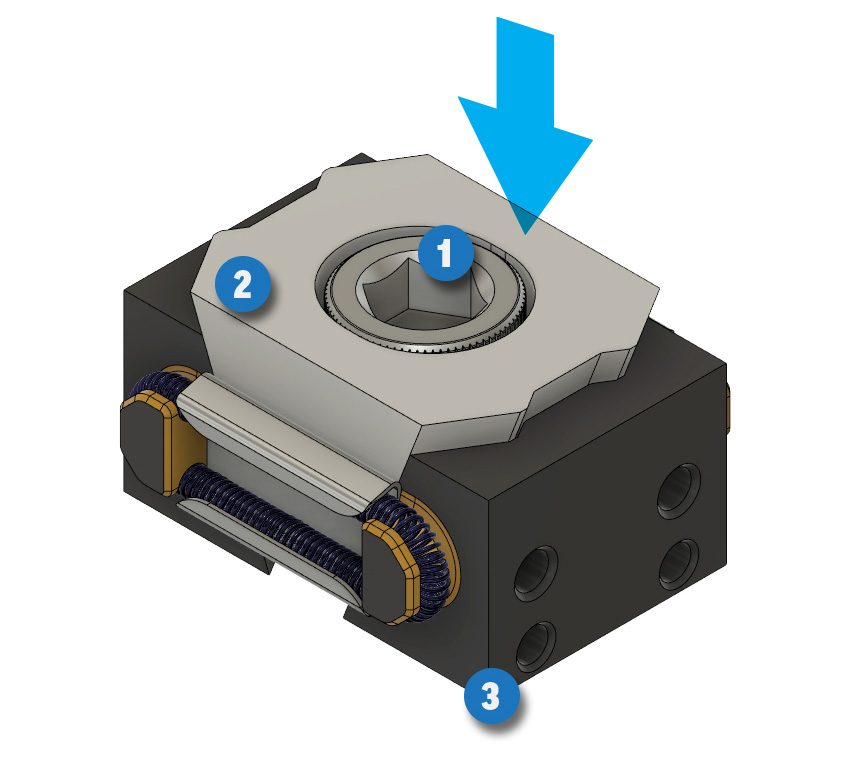

Low-Profile Spring Clamps

____________________________

Low-Profile Spring Clamps are a combination of a steel wedge and spring-loaded base designed to quickly clamp workpieces to fixture plates. Capable of clamping one or two workpieces with one clamp.

Features

- Low-profile clamp for maximum tool access

- Capable of clamping one or two parts using one clamp

- Various sizes and edge types available

- Quick to set up and customize

Different Edges for Different Purposes

- Flat Edge is designed to reduce marks on the workpiece while still possessing a high clamp force; best for second operations.

- Serrated Edge digs into the workpiece material for heavy-duty cutting; best for first operations.

- Hole Edge has threaded holes on the clamping faces to add compatible spacers to the spring clamp. This edge allows for parts of various dimensions to be clamped with the same fixture plate by interchanging the spacers.

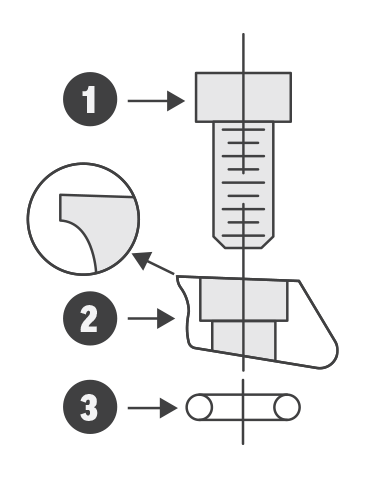

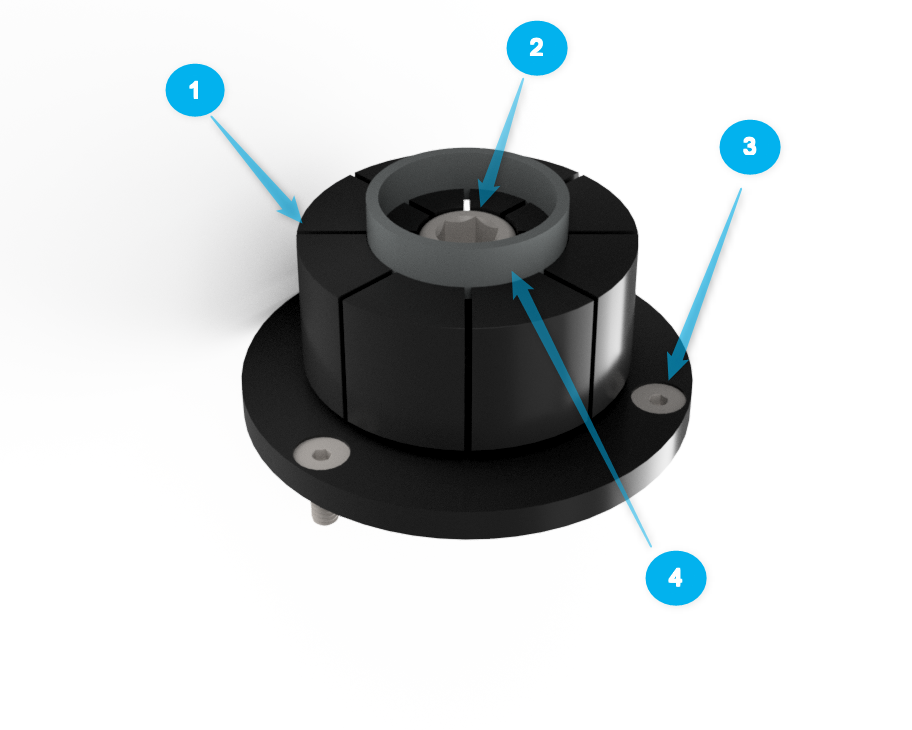

Flat Edge

1. Cap Screw | 2. Wedge | 3. Flat Edge

Serrated Edge

1. Cap Screw | 2. Wedge | 3. Serrated Edge

Hole Edge

1. Cap Screw | 2. Wedge | 3. Hole Edge

How Can I Fixture Parts Using Low Profile Spring Clamps?

These can quickly clamp multiple parts to help increase production. Check out below for examples of these clamps in use.

Square Parts

Using the flat or serrated low-profile spring clamps, square stock can be held by having the clamp act as a wedge, clamping the workpiece up against a machined or other part stop.

Round Parts

Using the hole low-profile spring clamp and the V-block spacer, round parts can be clamped by the V-block spacer clamping the workpiece up against a machined or other part stop.

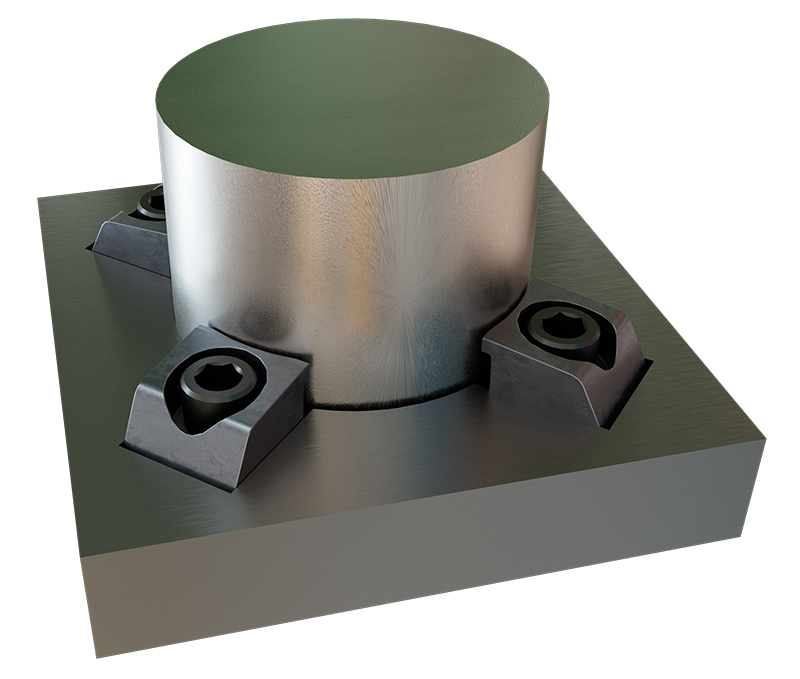

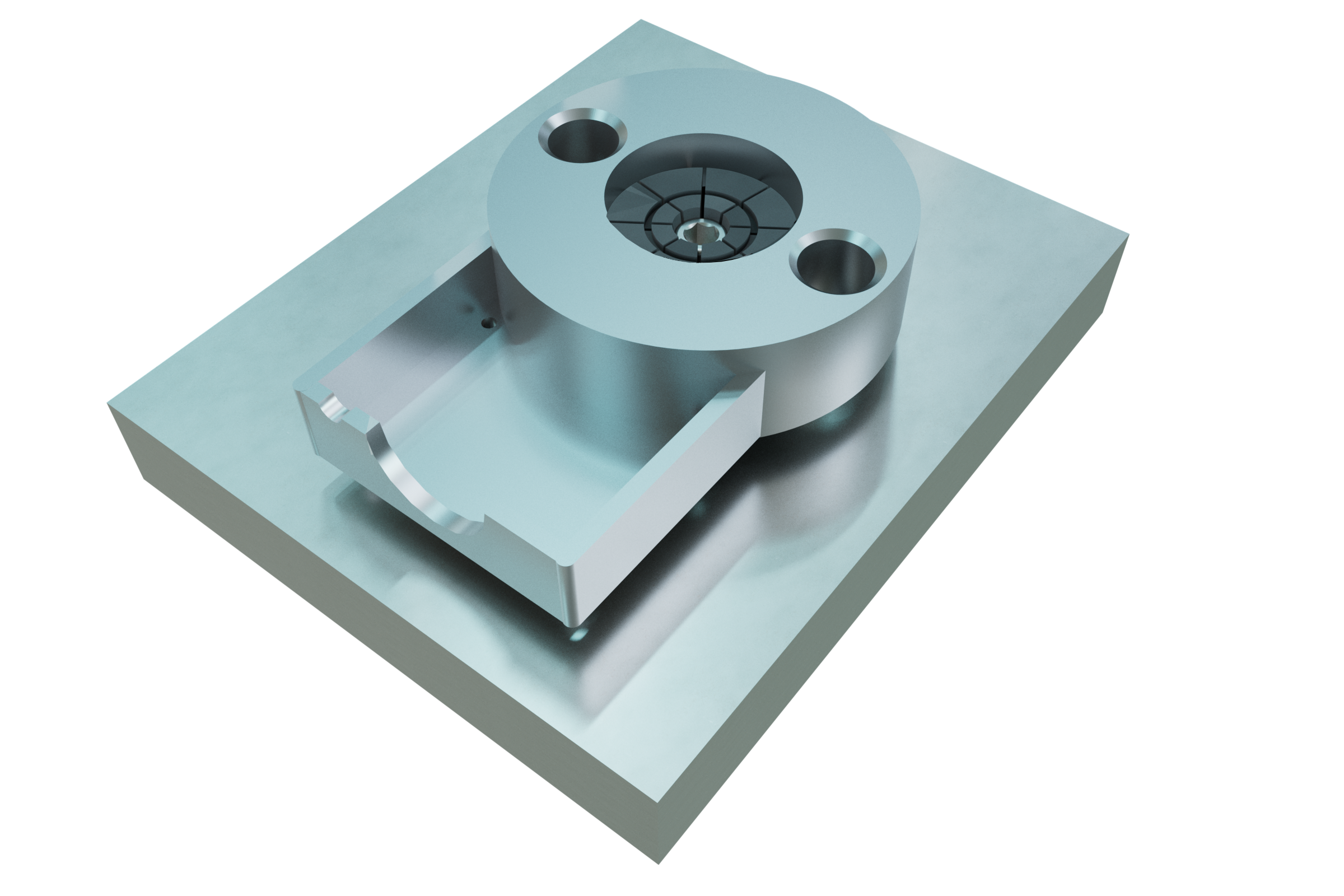

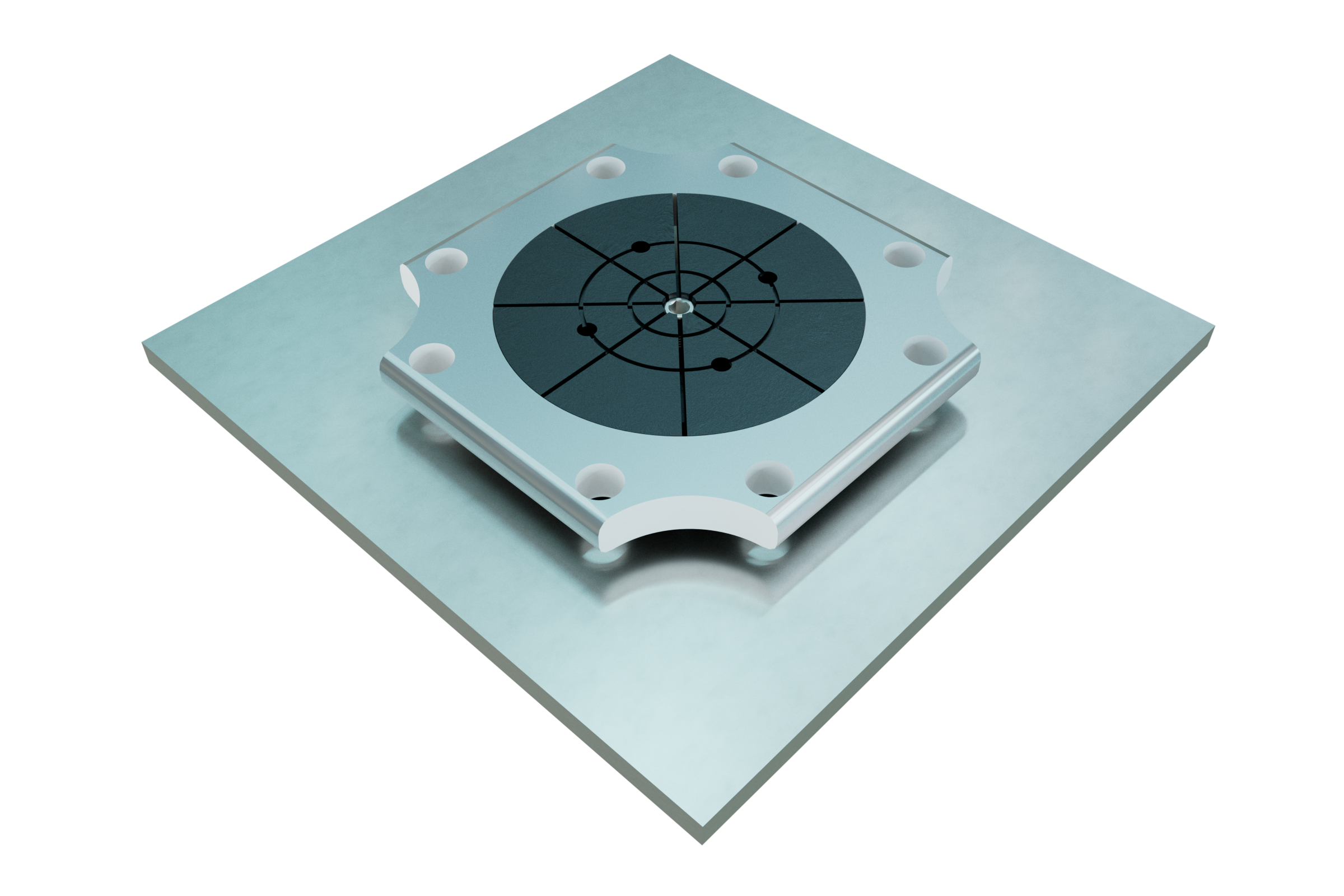

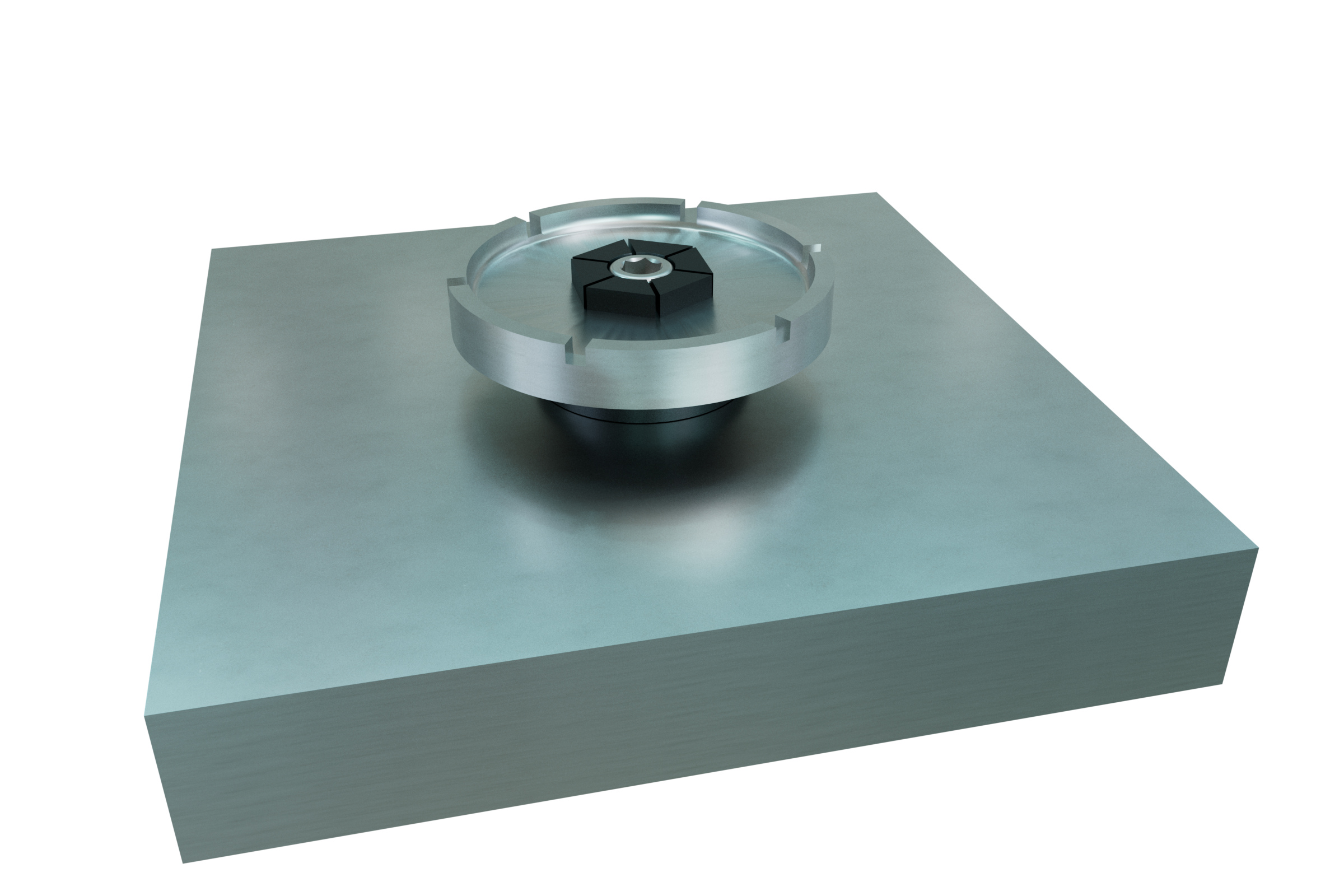

ID Xpansion Clamps

____________________________

ID Xpansion Clamps allow parts to be clamped by an inner diameter. The machinable clamp allows for custom sizes and shapes of ID features to be secured. The clamp is mounted to a fixture using tapped holes, and a center screw is tightened to apply outward force, securing the ID of a workpiece.

Made of 12L14 steel with black oxide coating (size #10 is made of 7075-T6 aluminum), these machinable clamps can secure internal diameters from 0.16" to 9.85" (4 - 250mm).

Features

- Low profile

- Easily machined to custom size

- Tool access to full length of all outer edges

- Ideal for secondary operations on mills and lathes

What’s Included

- ID Xpansion Clamp

- Tapered Screw

- Button Head Cap Screw (BHCS)

- ID Xpansion Clamp

- Tapered Screw

- Button Head Cap Screw (BHCS)

- Locking Ring(s)

Application Examples

Suitable for horizontal and vertical milling applications, or as an expanding mandrel on a lathe, the ID Xpansion Clamps can be used for a variety of applications.

ID Circular Xpansion

ID Circular Xpansion

ID Hexagonal Xpansion

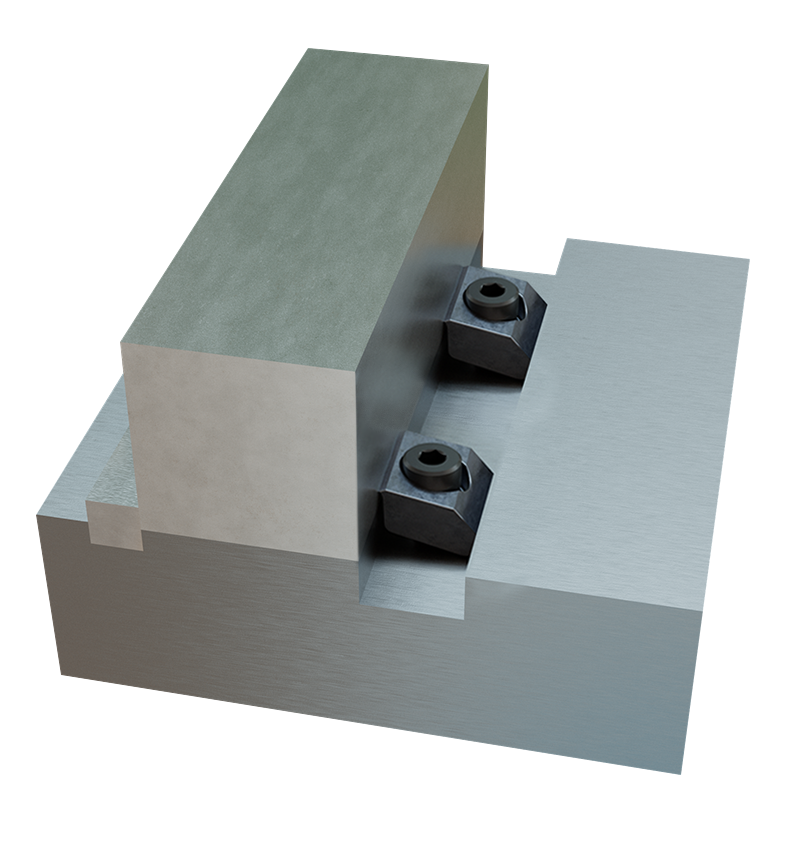

TalonGrip™ Clamps

____________________________

TalonGrip™ uses a serrated edge that creates more holding force than a smooth fixture wall. Use these on the fixed side of a fixture along with Pitbull or UniForce clamps.

Features

- Use on materials up to 40 HRC

- Low profile clamp for maximum tool clearance and minimum wasted material

- Designed for aggressive machining

Application Examples

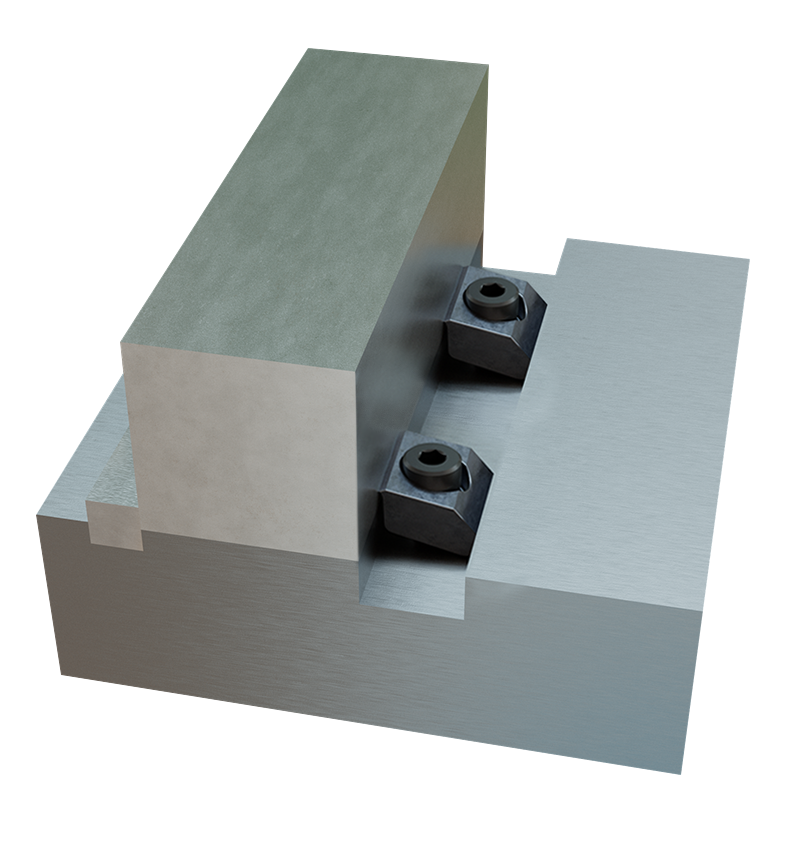

Paired with Pitbull Clamps

VersaGrip™ Clamps

____________________________

VersaGrip™ uses a serrated edge that creates more holding force than a smooth fixture wall. Use these on the fixed side of a fixture along with Pitbull or UniForce clamps. Can be used to hold odd shaped parts without custom fixturing.

Features

- Hardened to 55HRc

- Low profile clamp for maximum tool clearance and minimum wasted material

- Designed for aggressive machining

- Can be used to hold irregular shapes

- Heavy Duty version with more clamping height for more holding force

Application Examples

Square/Rectangle Parts Paired with Pitbull Clamps

Round Parts Paired with Pitbull Clamps

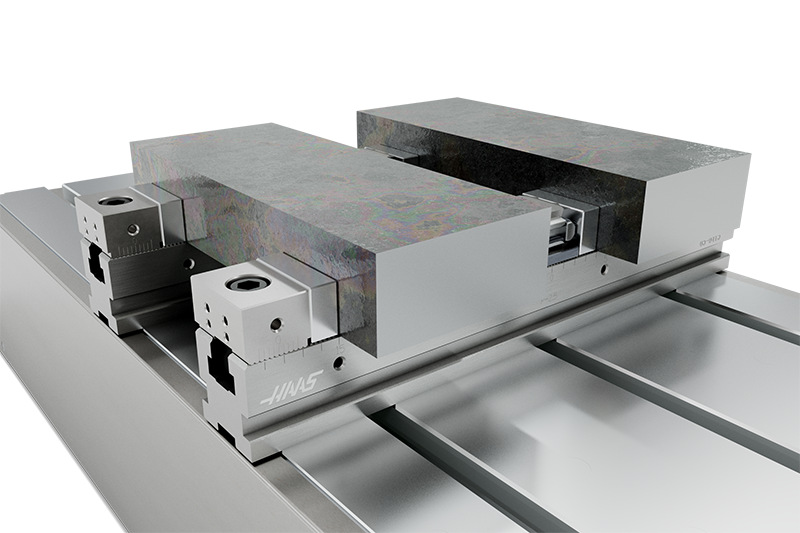

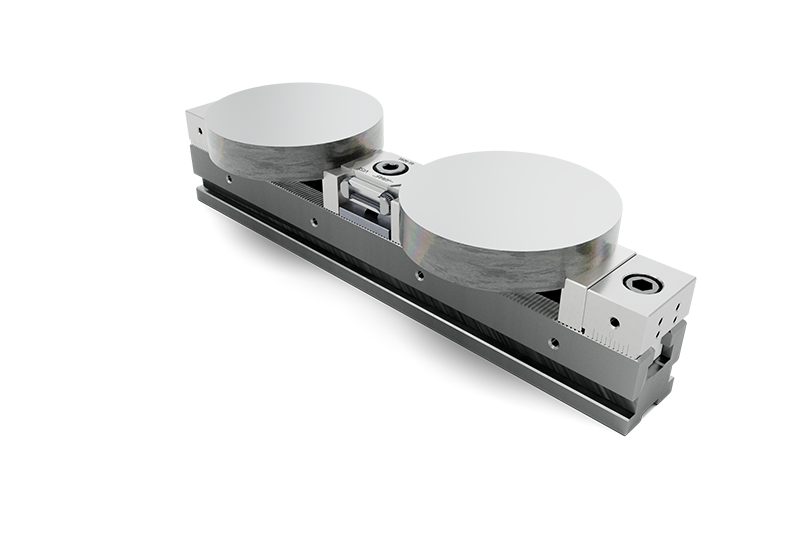

Rail Fixtures & Kits

____________________________

Rail Fixtures are a very versatile way to clamp your workpieces for machining. These fixtures can be quickly reconfigured for multiple applications and workpieces to best suit your shop’s needs!

Features

- Suitable for multiple workpieces

- High clamp force

- Quick and easy set up

- Available in 400, 500, and 600mm lengths

Using Rail Fixtures with Low-Profile Spring Clamps and Stops

Low-Profile Spring Clamp

1. Cap Screw | 2. Low-Profile Spring Clamp | 3. Base Plate | 4. T-Nut | 5. Rail Fixture

Workpiece Rail Stop

1. Cap Screw | 2. Rail Stop | 3. Rail Stop T-nut | 4. Rail Fixture

What Type of Parts Can I Hold Using Rail Fixtures?

Square/Rectangular Parts

Using the flat, serrated, or hole low-profile spring clamps, square stock can be held by having the clamp act as a wedge, clamping the workpiece against the rail stop.

Round/Custom Parts

Using the hole low-profile spring clamp and the rail soft Jaws, round and custom parts can be clamped, when soft jaws are machined to match your workpiece.

Application Examples

Tombstone Mounted

Table Mounted