-

máquinas

Main Menu

-

Fresadoras verticais

Fresadoras verticaisFresadoras verticais View All

Fresadoras verticais

Fresadoras verticaisFresadoras verticais View All- Fresadoras verticais

- Série VF

- Máquinas universais

- Série VR

- VP-5 prismático

- VMC com troca de paletes

- Mini fresadoras

- Máquinas de moldagem

- Centros de perfuração de alta velocidade

- Série Perfurar/Roscar/Fresar

- Fresadora Sala de Ferramentas

- Fresadoras compactas

- Série pórtico

- Routers de chapa SR

- VMC extragrande

- Fresadoras de coluna dupla

- Simulador de controlo

- Fresadora com carregador de peças automático

- Carregador de peças automático de carga lateral VMC/UMC

- Carregador de peças automático compacto

-

Soluções multi-eixo

Soluções multi-eixoSoluções multi-eixo View All

Soluções multi-eixo

Soluções multi-eixoSoluções multi-eixo View All -

Tornos

TornosTornos View All

Tornos

TornosTornos View All -

Fresadoras horizontais

Fresadoras horizontaisFresadoras horizontais View All

Fresadoras horizontais

Fresadoras horizontaisFresadoras horizontais View All -

Rotativos e Indexadores

Rotativos e IndexadoresRotativos e Indexadores View All

Rotativos e Indexadores

Rotativos e IndexadoresRotativos e Indexadores View All -

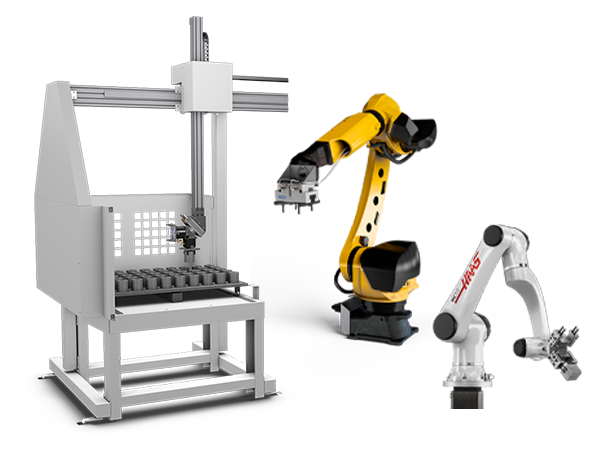

Sistemas de automatização

Sistemas de automatizaçãoSistemas de automatização View All

Sistemas de automatização

Sistemas de automatizaçãoSistemas de automatização View All -

Máquinas Desktop

Máquinas DesktopMáquinas Desktop View All

Máquinas Desktop

Máquinas DesktopMáquinas Desktop View All -

Comprar equipamento

Comprar equipamentoComprar equipamento View All

Comprar equipamento

Comprar equipamentoComprar equipamento View All

LIGAÇÕES RÁPIDAS Série especial Série especialFERRAMENTAS DE COMPRASQUER FALAR COM ALGUÉM?A Haas Factory Outlet (HFO) pode responder às suas perguntas e orientá-lo nas suas melhores opções.

CONTACT YOUR DISTRIBUTOR > -

-

Opções

Main Menu

-

Spindles

SpindlesSpindles View All

Spindles

SpindlesSpindles View All -

Trocadores da ferramenta

Trocadores da ferramentaTrocadores da ferramenta View All

Trocadores da ferramenta

Trocadores da ferramentaTrocadores da ferramenta View All -

4.º | 5.º eixo

4.º | 5.º eixo4.º | 5.º eixo View All

4.º | 5.º eixo

4.º | 5.º eixo4.º | 5.º eixo View All -

Torretas e ferramenta motorizada

Torretas e ferramenta motorizadaTorretas e ferramenta motorizada View All

Torretas e ferramenta motorizada

Torretas e ferramenta motorizadaTorretas e ferramenta motorizada View All -

Sondagem

SondagemSondagem View All

Sondagem

SondagemSondagem View All -

Gestão da limalha e do líquido de refrigeração

Gestão da limalha e do líquido de refrigeraçãoGestão da limalha e do líquido de refrigeração View All

Gestão da limalha e do líquido de refrigeração

Gestão da limalha e do líquido de refrigeraçãoGestão da limalha e do líquido de refrigeração View All -

O controlador Haas

O controlador HaasO controlador Haas View All

O controlador Haas

O controlador HaasO controlador Haas View All -

Opções de Produtos

Opções de ProdutosOpções de Produtos View All

Opções de Produtos

Opções de ProdutosOpções de Produtos View All -

Ferramentas e Fixação

Ferramentas e FixaçãoFerramentas e Fixação View All

Ferramentas e Fixação

Ferramentas e FixaçãoFerramentas e Fixação View All -

Dispositivo de aperto

Dispositivo de apertoDispositivo de aperto View All

Dispositivo de aperto

Dispositivo de apertoDispositivo de aperto View All -

Soluções de 5 eixos

Soluções de 5 eixosSoluções de 5 eixos View All

Soluções de 5 eixos

Soluções de 5 eixosSoluções de 5 eixos View All -

AUTOMATIZAÇÃO

AUTOMATIZAÇÃOAUTOMATIZAÇÃO View All

AUTOMATIZAÇÃO

AUTOMATIZAÇÃOAUTOMATIZAÇÃO View All

LIGAÇÕES RÁPIDAS Série especial Série especialFERRAMENTAS DE COMPRASQUER FALAR COM ALGUÉM?A Haas Factory Outlet (HFO) pode responder às suas perguntas e orientá-lo nas suas melhores opções.

CONTACT YOUR DISTRIBUTOR > -

-

Why Haas

Main Menu

Descubra a Diferença da Haas

-

Assistência

Main Menu

- Vídeos Main Menu