-

strojevi

Main Menu

-

Vertikalne glodalice

Vertikalne glodaliceVertikalne glodalice View All

Vertikalne glodalice

Vertikalne glodaliceVertikalne glodalice View All- Vertikalne glodalice

- VF serija

- Univerzalni strojevi

- VR serija

- VP-5 prizmatski stroj

- VMC-ovi za izmjenu paleta

- Male glodalice

- Strojevi za modeliranje

- Centri za bušenje velike brzine

- Serija strojeva za bušenje/narezivanje/glodanje

- Alatne glodalice

- Kompaktne glodalice

- Serije pokretnih postolja

- SR Usmjernici za ploče

- Iznimno veliki VMC strojevi

- Glodalice s dvostrukim stupcem

- Upravljački simulator

- Automatski sustav za dodavanje sirovca za glodalicu

- VMC/UMC automatski sustav za dodavanje sirovca s bočnim punjenjem

- Kompaktni APL

-

Višeosna rješenja

Višeosna rješenjaVišeosna rješenja View All

Višeosna rješenja

Višeosna rješenjaVišeosna rješenja View All -

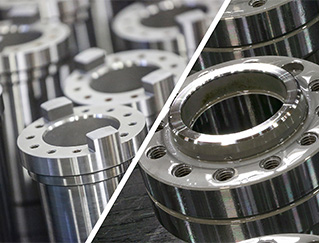

Tokarilica

TokarilicaTokarilica View All

Tokarilica

TokarilicaTokarilica View All -

Horizontalne glodalice

Horizontalne glodaliceHorizontalne glodalice View All

Horizontalne glodalice

Horizontalne glodaliceHorizontalne glodalice View All -

rotacioni proizvodi i indekseri

rotacioni proizvodi i indekserirotacioni proizvodi i indekseri View All

rotacioni proizvodi i indekseri

rotacioni proizvodi i indekserirotacioni proizvodi i indekseri View All -

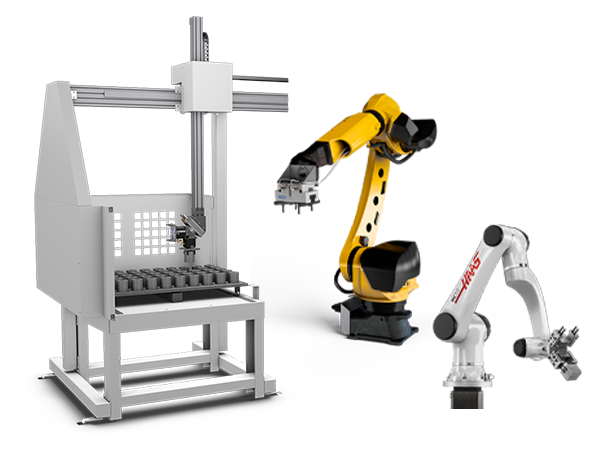

Sustavi automatizacije

Sustavi automatizacijeSustavi automatizacije View All

Sustavi automatizacije

Sustavi automatizacijeSustavi automatizacije View All -

Desktop strojevi

Desktop strojeviDesktop strojevi View All

Desktop strojevi

Desktop strojeviDesktop strojevi View All -

Oprema za radionice

Oprema za radioniceOprema za radionice View All

Oprema za radionice

Oprema za radioniceOprema za radionice View All

BRZE POVEZNICE Posebne serije Posebne serijeŽELITE RAZGOVARATI S NEKIM?Haas tvornički dućan (outlet) (HFO) može odgovoriti na vaša pitanja i provesti vas kroz najbolje opcije.

CONTACT YOUR DISTRIBUTOR > -

-

Opcije

Main Menu

-

Glavna vretena

Glavna vretenaGlavna vretena View All

Glavna vretena

Glavna vretenaGlavna vretena View All -

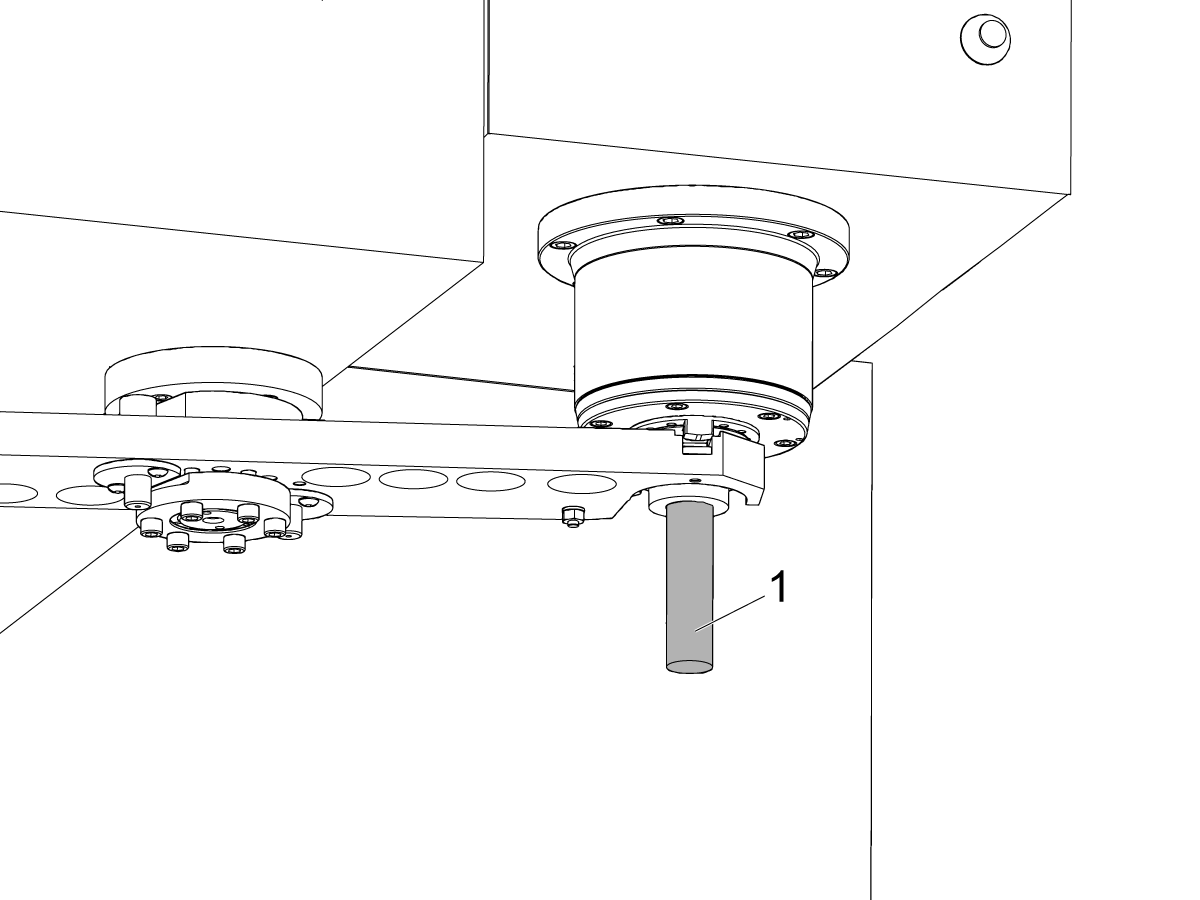

Izmjenjivači alata

Izmjenjivači alataIzmjenjivači alata View All

Izmjenjivači alata

Izmjenjivači alataIzmjenjivači alata View All -

4- | 5-osni

4- | 5-osni4- | 5-osni View All

4- | 5-osni

4- | 5-osni4- | 5-osni View All -

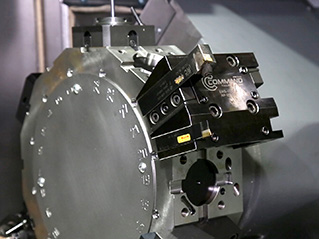

Revolveri i pogonjeni alati

Revolveri i pogonjeni alatiRevolveri i pogonjeni alati View All

Revolveri i pogonjeni alati

Revolveri i pogonjeni alatiRevolveri i pogonjeni alati View All -

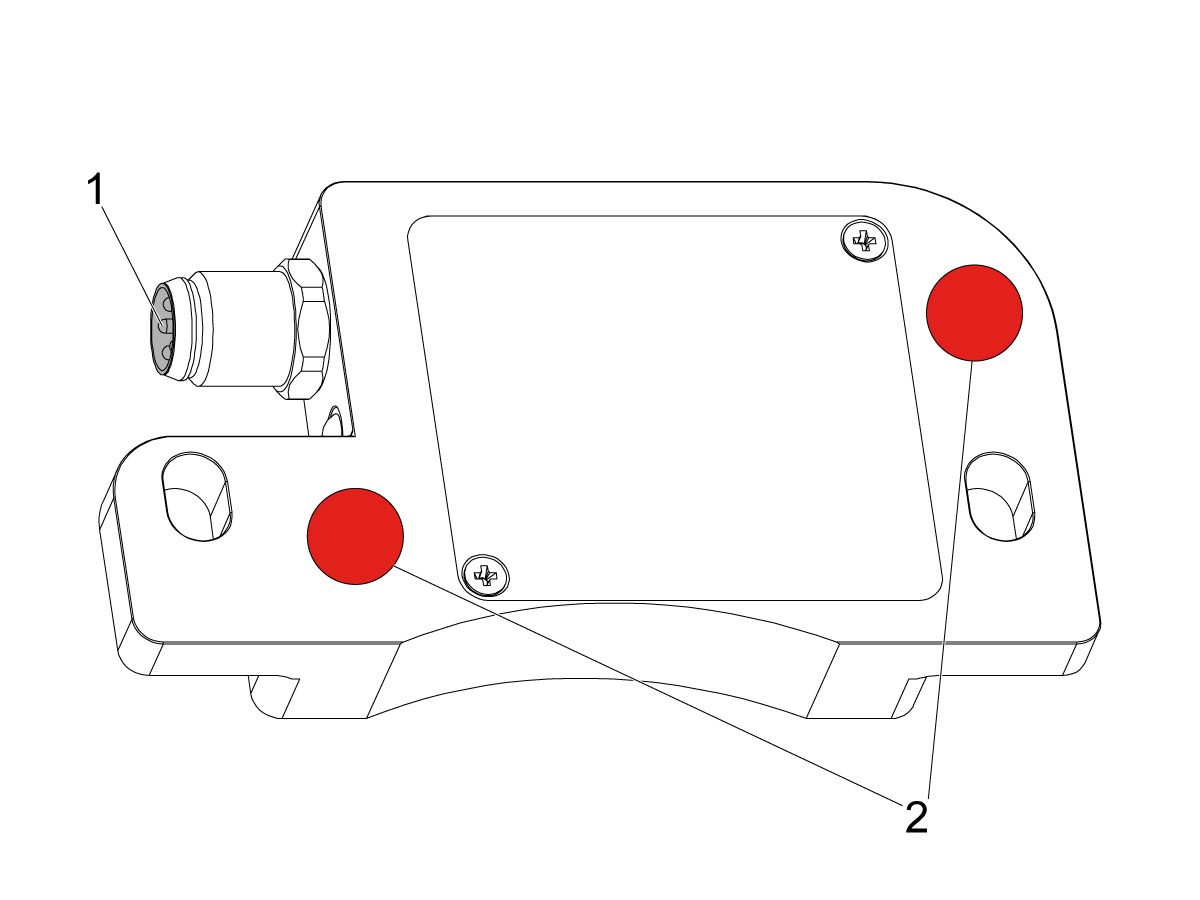

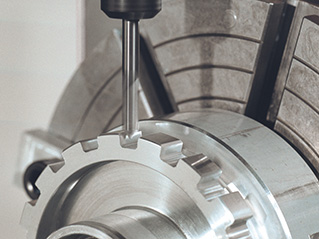

Sondiranje

SondiranjeSondiranje View All

Sondiranje

SondiranjeSondiranje View All -

Upravljanje strugotinom i rashladnim sredstvima

Upravljanje strugotinom i rashladnim sredstvimaUpravljanje strugotinom i rashladnim sredstvima View All

Upravljanje strugotinom i rashladnim sredstvima

Upravljanje strugotinom i rashladnim sredstvimaUpravljanje strugotinom i rashladnim sredstvima View All -

Haas upravljačka naprava

Haas upravljačka napravaHaas upravljačka naprava View All

Haas upravljačka naprava

Haas upravljačka napravaHaas upravljačka naprava View All -

Opcije proizvoda

Opcije proizvodaOpcije proizvoda View All

Opcije proizvoda

Opcije proizvodaOpcije proizvoda View All -

Alati i Stezanje i prihvat sirovca

Alati i Stezanje i prihvat sirovcaAlati i Stezanje i prihvat sirovca View All

Alati i Stezanje i prihvat sirovca

Alati i Stezanje i prihvat sirovcaAlati i Stezanje i prihvat sirovca View All -

Držač obratka

Držač obratkaDržač obratka View All

Držač obratka

Držač obratkaDržač obratka View All -

5-osna rješenja

5-osna rješenja5-osna rješenja View All

5-osna rješenja

5-osna rješenja5-osna rješenja View All -

Automatizacija

AutomatizacijaAutomatizacija View All

Automatizacija

AutomatizacijaAutomatizacija View All

BRZE POVEZNICE Posebne serije Posebne serijeŽELITE RAZGOVARATI S NEKIM?Haas tvornički dućan (outlet) (HFO) može odgovoriti na vaša pitanja i provesti vas kroz najbolje opcije.

CONTACT YOUR DISTRIBUTOR > -

-

Why Haas

Main Menu

Otkrijte Haas razliku

-

Servis

Main Menu

- Videozapisi Main Menu