-

maskiner

Main Menu

-

VMT-serien

VMT-serienVMT-serien View All

VMT-serien

VMT-serienVMT-serien View All- VMT-serien

- VF-serien

- UMC-serien

- VR-serien

- Prismatisk VP-5

- VMC med palettväxlare

- Minimill

- VM-serien

- Höghastighetsborrmaskiner

- Drill/Tap/Mill-serien

- Toolroom-serien

- Compact Mill

- Portalfräsar

- SR skivmatningsbord

- VS-serien

- Fräsar med dubbla pelare

- Styrsimulator

- Portalrobot för fräs

- APL för laddning av VMC/UMC från sidan

- Kompakt portalrobot

-

Fleraxlade lösningar

Fleraxlade lösningarFleraxlade lösningar View All

Fleraxlade lösningar

Fleraxlade lösningarFleraxlade lösningar View All -

Svarvar

SvarvarSvarvar View All

Svarvar

SvarvarSvarvar View All -

Horisontalfräsar

HorisontalfräsarHorisontalfräsar View All

Horisontalfräsar

HorisontalfräsarHorisontalfräsar View All -

Rundmatningsbord och indexerare

Rundmatningsbord och indexerareRundmatningsbord och indexerare View All

Rundmatningsbord och indexerare

Rundmatningsbord och indexerareRundmatningsbord och indexerare View All -

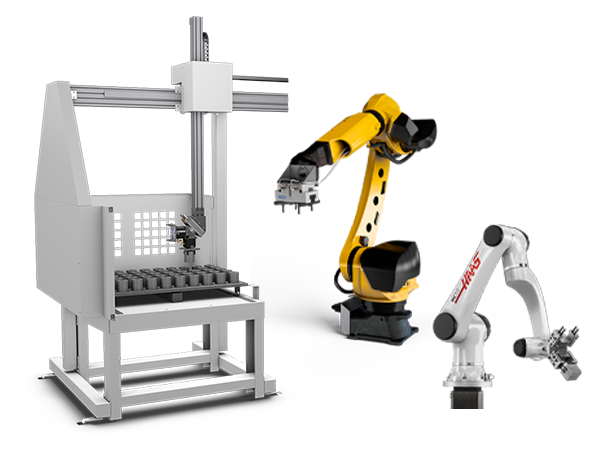

Automatiseringssystem

AutomatiseringssystemAutomatiseringssystem View All

Automatiseringssystem

AutomatiseringssystemAutomatiseringssystem View All -

Skrivbordsmaskiner

SkrivbordsmaskinerSkrivbordsmaskiner View All

Skrivbordsmaskiner

SkrivbordsmaskinerSkrivbordsmaskiner View All -

Verkstadsutrustning

VerkstadsutrustningVerkstadsutrustning View All

Verkstadsutrustning

VerkstadsutrustningVerkstadsutrustning View All

SNABBLÄNKAR Specialserie SpecialserieKÖPA VERKTYGVILL DU KOMMA I KONTAKT MED OSS?Din Haas-leverantör (HFO) kan besvara alla dina frågor och diskutera vilka lösningar som är bäst för dig.

CONTACT YOUR DISTRIBUTOR > -

-

Alternativ

Main Menu

-

Spindlar

SpindlarSpindlar View All

Spindlar

SpindlarSpindlar View All -

Verktygsväxlare

VerktygsväxlareVerktygsväxlare View All

Verktygsväxlare

VerktygsväxlareVerktygsväxlare View All -

4:e | 5:e-axlade

4:e | 5:e-axlade4:e | 5:e-axlade View All

4:e | 5:e-axlade

4:e | 5:e-axlade4:e | 5:e-axlade View All -

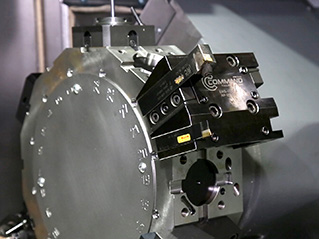

Revolvrar och roterande verktyg

Revolvrar och roterande verktygRevolvrar och roterande verktyg View All

Revolvrar och roterande verktyg

Revolvrar och roterande verktygRevolvrar och roterande verktyg View All -

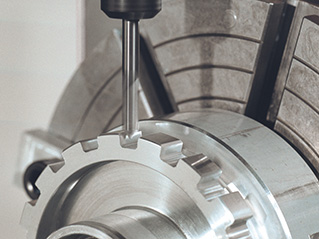

Sondering

SonderingSondering View All

Sondering

SonderingSondering View All -

Hantering av spån och kylmedel

Hantering av spån och kylmedelHantering av spån och kylmedel View All

Hantering av spån och kylmedel

Hantering av spån och kylmedelHantering av spån och kylmedel View All -

Haas styrsystem

Haas styrsystemHaas styrsystem View All

Haas styrsystem

Haas styrsystemHaas styrsystem View All -

Produktalternativ

ProduktalternativProduktalternativ View All

Produktalternativ

ProduktalternativProduktalternativ View All -

Verktyg och fixturtillbehör

Verktyg och fixturtillbehörVerktyg och fixturtillbehör View All

Verktyg och fixturtillbehör

Verktyg och fixturtillbehörVerktyg och fixturtillbehör View All -

Uppspänningsanordning

UppspänningsanordningUppspänningsanordning View All

Uppspänningsanordning

UppspänningsanordningUppspänningsanordning View All -

5-axliga lösningar

5-axliga lösningar5-axliga lösningar View All

5-axliga lösningar

5-axliga lösningar5-axliga lösningar View All -

Automatisering

AutomatiseringAutomatisering View All

Automatisering

AutomatiseringAutomatisering View All

SNABBLÄNKAR Specialserie SpecialserieKÖPA VERKTYGVILL DU KOMMA I KONTAKT MED OSS?Din Haas-leverantör (HFO) kan besvara alla dina frågor och diskutera vilka lösningar som är bäst för dig.

CONTACT YOUR DISTRIBUTOR > -

-

Why Haas

Main Menu

Upptäck skillnaden med Haas

-

Service

Main Menu

Välkommen till Haas Service

- Videor Main Menu

.png)

-v4.png)

-v4.png)

-v4.png)

-V3.png)

%20V2.png)