-

stroji

Main Menu

-

Vertikalni rezkarji

Vertikalni rezkarjiVertikalni rezkarji View All

Vertikalni rezkarji

Vertikalni rezkarjiVertikalni rezkarji View All- Vertikalni rezkarji

- VF Serija

- Univerzalni stroji

- Serija VF

- VP-5 prizmatično

- VMC z menjavo palet

- Stroji Mini Mill

- Kalupni stroji

- Visokohitrostni vrtalni centri

- Serija Drill/Tap/Mill

- Rezkarji Toolroom Mill

- Kompaktni rezkarji

- Serija Gantry

- SR usmerjevalniki pločevine

- Izjemno velik vertikalni obdelovalni center (VMC)

- Rezkarji z dvema stebroma

- Simulator krmilja

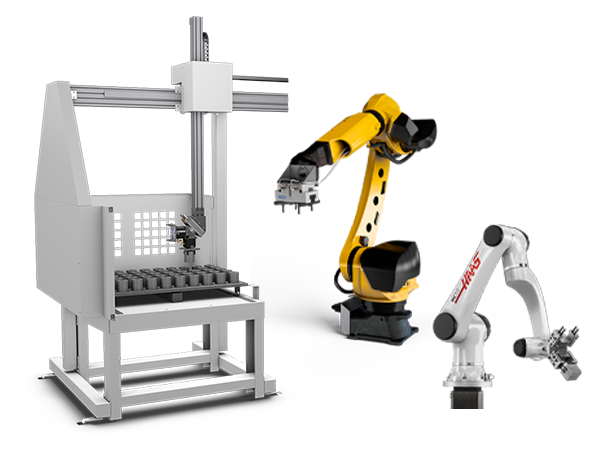

- AVTOMATSKI NALAGALNI SISTEM ZA REZKAR

- VMC/UMC APL na strani

- Kompaktni avtomatski nalagalni sistem

-

Večosne rešitve

Večosne rešitveVečosne rešitve View All

Večosne rešitve

Večosne rešitveVečosne rešitve View All -

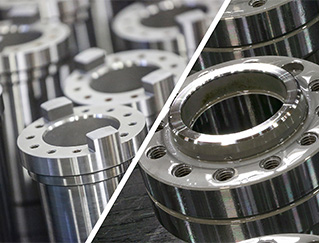

Stružnice

StružniceStružnice View All

Stružnice

StružniceStružnice View All -

Horizontalni rezkarji

Horizontalni rezkarjiHorizontalni rezkarji View All

Horizontalni rezkarji

Horizontalni rezkarjiHorizontalni rezkarji View All -

Rotacijske mize in indekserji

Rotacijske mize in indekserjiRotacijske mize in indekserji View All

Rotacijske mize in indekserji

Rotacijske mize in indekserjiRotacijske mize in indekserji View All -

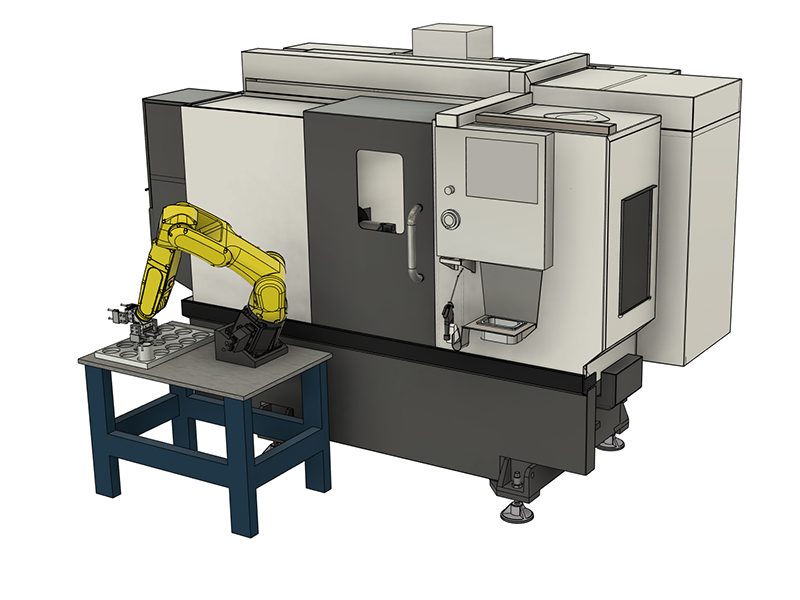

Avtomatizirani sistemi

Avtomatizirani sistemiAvtomatizirani sistemi View All

Avtomatizirani sistemi

Avtomatizirani sistemiAvtomatizirani sistemi View All -

Namizni stroji

Namizni strojiNamizni stroji View All

Namizni stroji

Namizni strojiNamizni stroji View All -

Oprema za delavnice

Oprema za delavniceOprema za delavnice View All

Oprema za delavnice

Oprema za delavniceOprema za delavnice View All

HITRE POVEZAVE Posebna serija Posebna serijaORODJA ZA NAKUPOVANJESE ŽELITE S KOM POGOVORITI?Tovarniška izpostava Haas (HFO) lahko odgovori na vaša vprašanja in vam predstavi vaše najboljše možnosti.

CONTACT YOUR DISTRIBUTOR > -

-

Možnosti

Main Menu

-

Vretena

VretenaVretena View All

Vretena

VretenaVretena View All -

Menjalci orodja

Menjalci orodjaMenjalci orodja View All

Menjalci orodja

Menjalci orodjaMenjalci orodja View All -

4. | 5. os

4. | 5. os4. | 5. os View All

4. | 5. os

4. | 5. os4. | 5. os View All -

Revolverji in gnana orodja

Revolverji in gnana orodjaRevolverji in gnana orodja View All

Revolverji in gnana orodja

Revolverji in gnana orodjaRevolverji in gnana orodja View All -

Merjenje s sondo

Merjenje s sondoMerjenje s sondo View All

Merjenje s sondo

Merjenje s sondoMerjenje s sondo View All -

Obvladovanje odrezkov in emulzije

Obvladovanje odrezkov in emulzijeObvladovanje odrezkov in emulzije View All

Obvladovanje odrezkov in emulzije

Obvladovanje odrezkov in emulzijeObvladovanje odrezkov in emulzije View All -

Krmilje Haas

Krmilje HaasKrmilje Haas View All

Krmilje Haas

Krmilje HaasKrmilje Haas View All -

Opcije izdelka

Opcije izdelkaOpcije izdelka View All

Opcije izdelka

Opcije izdelkaOpcije izdelka View All -

Orodje in vpenjanje

Orodje in vpenjanjeOrodje in vpenjanje View All

Orodje in vpenjanje

Orodje in vpenjanjeOrodje in vpenjanje View All -

Vpenjanje obdelovanca

Vpenjanje obdelovancaVpenjanje obdelovanca View All

Vpenjanje obdelovanca

Vpenjanje obdelovancaVpenjanje obdelovanca View All -

5-osne rešitve

5-osne rešitve5-osne rešitve View All

5-osne rešitve

5-osne rešitve5-osne rešitve View All -

Avtomatizacija

AvtomatizacijaAvtomatizacija View All

Avtomatizacija

AvtomatizacijaAvtomatizacija View All

HITRE POVEZAVE Posebna serija Posebna serijaORODJA ZA NAKUPOVANJESE ŽELITE S KOM POGOVORITI?Tovarniška izpostava Haas (HFO) lahko odgovori na vaša vprašanja in vam predstavi vaše najboljše možnosti.

CONTACT YOUR DISTRIBUTOR > -

-

Why Haas

Main Menu

Spoznajte Haasovo razliko

-

Servis

Main Menu

- Videoposnetki Main Menu

-setup/Machines-Top-View.png)

-setup/FANUC%20DCS%20Safe%20Zone%20Setup%20J2%20Measuring%201.jpg)

-setup/step-2.png)

-setup/Table.jpg)

-setup/step-4.png)

-setup/step-5.png)

-setup/step-6.png)

-setup/step-7.png)

-setup/step-8.png)

-setup/DCS-User-Frame-Setup-1.png)

-setup/DCS-User-Frame-30-degree-Y-axis.png)

-setup/DCS-User-Frame-35-degree-Z-axis.png)

-setup/DCS-User-Frame-Setup-2-2.png)

-setup/DCS-Cartesian-Position-Check-Setup-1.png)

-setup/DCS-Cartesian-Position-Check-Setup-2.png)

-setup/DCS-Cartesian-Position-Check-Setup-3-2.png)

-setup/DCS-Cartesian-Position-Visualization-1.png)

-setup/HMI%20iPendant%2034.jpg)

-setup/Verify-DCS-Zone-Jogging.png)