-

设备

Main Menu

-

立式加工中心

立式加工中心立式加工中心 View All

-

多轴解决方案

多轴解决方案多轴解决方案 View All

-

车削中心

车削中心车削中心 View All

-

卧式加工中心

卧式加工中心卧式加工中心 View All

-

转台和分度器

转台和分度器转台和分度器 View All

-

自动化系统

自动化系统自动化系统 View All

-

桌面机床

桌面机床桌面机床 View All

-

车间设备

车间设备车间设备 View All

-

袖珍机床

袖珍机床袖珍机床 View All

采购指南 -

立式加工中心

-

选项

Main Menu

-

主轴

主轴主轴 View All

主轴

主轴主轴 View All -

刀库

刀库刀库 View All

刀库

刀库刀库 View All -

第 4 轴 |第 5 轴

第 4 轴 |第 5 轴第 4 轴 |第 5 轴 View All

第 4 轴 |第 5 轴

第 4 轴 |第 5 轴第 4 轴 |第 5 轴 View All -

刀塔和动力刀

刀塔和动力刀刀塔和动力刀 View All

刀塔和动力刀

刀塔和动力刀刀塔和动力刀 View All -

探测

探测探测 View All

探测

探测探测 View All -

切屑和冷却液管理

切屑和冷却液管理切屑和冷却液管理 View All

切屑和冷却液管理

切屑和冷却液管理切屑和冷却液管理 View All -

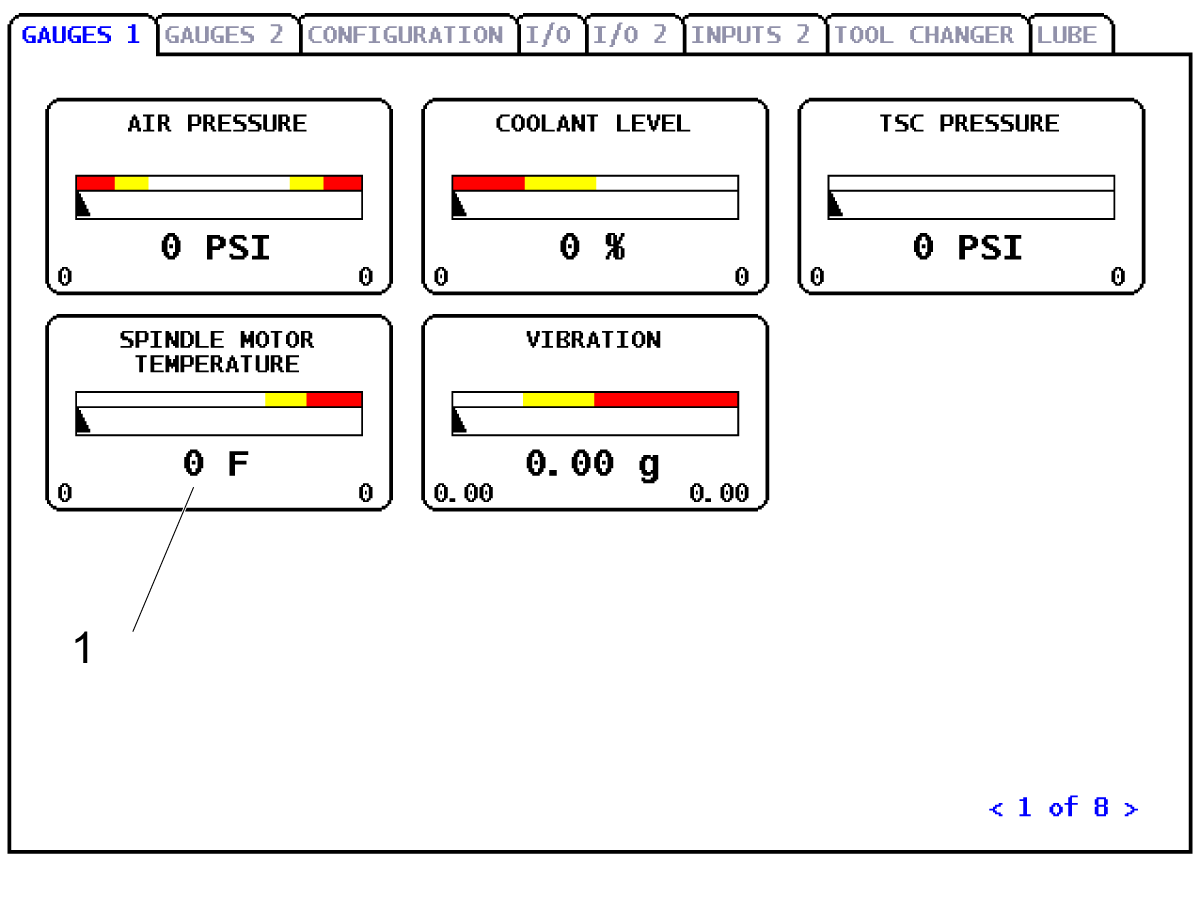

Haas 控制系统

Haas 控制系统Haas 控制系统 View All

Haas 控制系统

Haas 控制系统Haas 控制系统 View All -

产品选项

产品选项产品选项 View All

产品选项

产品选项产品选项 View All -

刀具和夹具

刀具和夹具刀具和夹具 View All

刀具和夹具

刀具和夹具刀具和夹具 View All -

工件夹具

工件夹具工件夹具 View All

工件夹具

工件夹具工件夹具 View All -

5 轴解决方案

5 轴解决方案5 轴解决方案 View All

5 轴解决方案

5 轴解决方案5 轴解决方案 View All -

自动化

自动化自动化 View All

自动化

自动化自动化 View All

采购指南 -

-

Why Haas

Main Menu

-

服务

Main Menu

- 视频 Main Menu

-

Main Menu

采购指南