-

machines

Main Menu

-

Vertical Mills

Vertical MillsVertical Mills View All

- Vertical Mills

- VF Series

- Universal Machines

- VR Series

- VP-5 Prismatic

- Pallet-Changing VMCs

- Mini Mills

- Mold Machines

- High-Speed Drill Centers

- Drill/Tap/ Mill Series

- Toolroom Mills

- Compact Mills

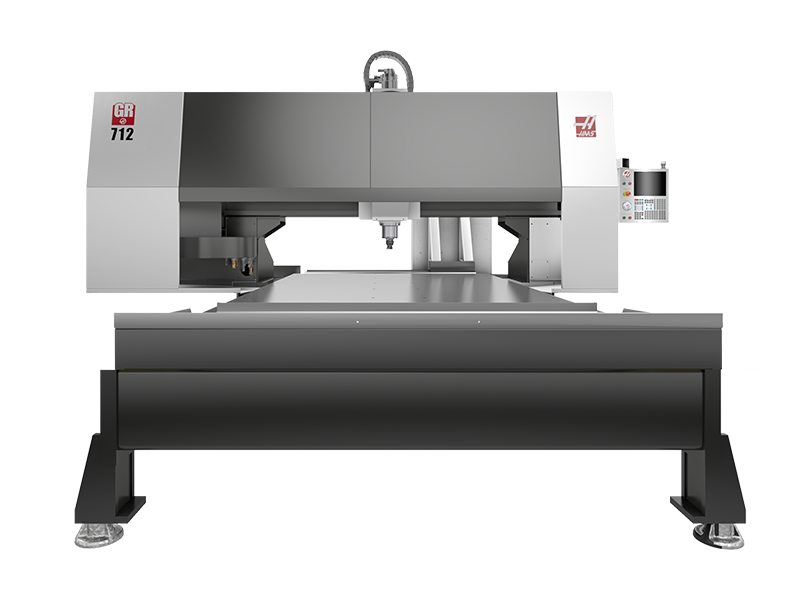

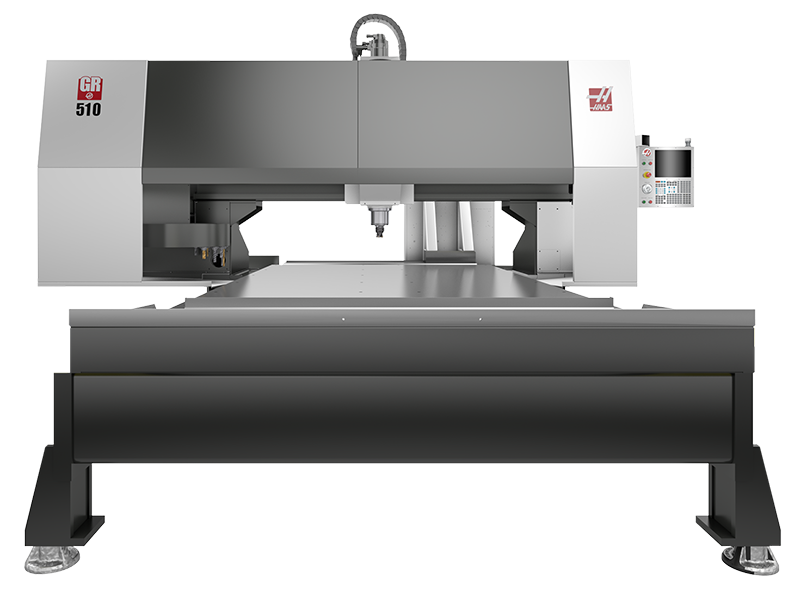

- Gantry Series

- SR Sheet Routers

- Extra-Large VMC

- Double-Column Mills

- Pocket Mill

- Mill Automatic Parts Loader

- VMC/UMC Side-Loading Automatic Parts Loader

- Compact Automatic Parts Loader

-

Multi-Axis Solutions

Multi-Axis SolutionsMulti-Axis Solutions View All

-

Lathes

LathesLathes View All

-

Horizontal Mills

Horizontal MillsHorizontal Mills View All

-

Rotaries & Indexers

Rotaries & IndexersRotaries & Indexers View All

-

Special Series

Special SeriesSpecial Series View All

-

Automation Systems

Automation SystemsAutomation Systems View All

-

Desktop Machines

Desktop MachinesDesktop Machines View All

-

Shop Equipment

Shop EquipmentShop Equipment View All

-

Pocket Machines

Pocket MachinesPocket Machines View All

QUICK LINKS Special Series Special SeriesSHOPPING TOOLSWANT TO TALK TO SOMEONE?A Haas Factory Outlet (HFO) can answer your questions, and walk you through your best options.

CONTACT YOUR DISTRIBUTOR > -

Vertical Mills

-

Options

Main Menu

-

/VOP-new-way-to-save.gif) Value Option Packages

Value Option PackagesValue Option Packages View All

Value Option Packages

Value Option PackagesValue Option Packages View All -

Spindles

SpindlesSpindles View All

Spindles

SpindlesSpindles View All -

Tool Changers

Tool ChangersTool Changers View All

Tool Changers

Tool ChangersTool Changers View All -

4th- | 5th-Axis

4th- | 5th-Axis4th- | 5th-Axis View All

4th- | 5th-Axis

4th- | 5th-Axis4th- | 5th-Axis View All -

Turrets & Live Tooling

Turrets & Live ToolingTurrets & Live Tooling View All

Turrets & Live Tooling

Turrets & Live ToolingTurrets & Live Tooling View All -

Probing

ProbingProbing View All

Probing

ProbingProbing View All -

Chip & Coolant Management

Chip & Coolant ManagementChip & Coolant Management View All

Chip & Coolant Management

Chip & Coolant ManagementChip & Coolant Management View All -

The Haas Control

The Haas ControlThe Haas Control View All

The Haas Control

The Haas ControlThe Haas Control View All -

Product Options

Product OptionsProduct Options View All

Product Options

Product OptionsProduct Options View All -

Tooling & Fixturing

Tooling & FixturingTooling & Fixturing View All

Tooling & Fixturing

Tooling & FixturingTooling & Fixturing View All -

Workholding

WorkholdingWorkholding View All

Workholding

WorkholdingWorkholding View All -

5-Axis Solutions

5-Axis Solutions5-Axis Solutions View All

5-Axis Solutions

5-Axis Solutions5-Axis Solutions View All

QUICK LINKS Special Series Special SeriesSHOPPING TOOLSWANT TO TALK TO SOMEONE?A Haas Factory Outlet (HFO) can answer your questions, and walk you through your best options.

CONTACT YOUR DISTRIBUTOR > -

-

Why Haas

Main Menu

Discover the Haas Difference

-

Service

Main Menu

Welcome to Haas Service

- Videos Main Menu

-

Main Menu

QUICK LINKS Special Series Special SeriesSHOPPING TOOLSWANT TO TALK TO SOMEONE?

A Haas Factory Outlet (HFO) can answer your questions, and walk you through your best options.

CONTACT YOUR DISTRIBUTOR > -

Haas Tooling

Main Menu

- Haas Tooling

-

Winner's CircleWinner's Circle Shop All

-

Winner's CircleWinner's Circle Shop All

-

Today’s Hot DealsToday’s Hot Deals Shop All

-

ClearanceClearance Shop All

-

Measuring & InspectionMeasuring & Inspection Shop All

- Probe Kits & Accessories

- Edge & Center Finders

- Comparative Measuring Gauges

- Height Gauges

- Calipers

- Threaded Plug & Ring Gauges

- Gauge Blocks

- Pin Gauges

- Drop Indicators

- Dial Test Indicators

- Bore Gauges

- Indicator Accessories

- V Blocks

- Setup Blocks

- Depth Measuring

- Micrometers

- Micrometer Accessories

- Micrometer Kits

- Bore Gauge Kits

- Starter Kits

- Indicator Kits

- Caliper Kits

- Toolholder Check Station

- Height Setters

- Coordinate Measuring Machines

- Coating Thickness Gauges

- Hardness Tester

-

Automation AccessoriesAutomation Accessories Shop All

-

Shop SupportShop Support Shop All

-

Mill ToolholdingMill Toolholding Shop All

-

Mill ToolingMill Tooling Shop All

- Shell Mill Bodies

- Milling Inserts

- End Mills

- Chamfer Mills & Inserts

- Indexable End Mill Bodies

- Ball End Mills

- Chamfer End Mills

- Roughing End Mills

- Indexable Ball End Mills & Inserts

- Shell Mill Kits

- Chamfer Mill Kits

- Indexable End Mill Kits

- Dovetail Cutters

- Indexable Dovetail Cutters

- Engraving End Mills

- Rotary Burrs / Die Grinding Bits

- Keyseat Cutters

- Corner Rounding End Mills

- Slot Mill Bodies

- CNC Router Bits For Wood

- Indexable CNC Router Bits & Inserts

-

Boring SystemsBoring Systems Shop All

-

Mill WorkholdingMill Workholding Shop All

-

Lathe ToolholdingLathe Toolholding Shop All

-

Lathe ToolingLathe Tooling Shop All

- Cut-Off Tool Blocks & Blades

- Cut-Off Tooling Kits

- Turning Inserts

- Grooving & Cut-Off Tools

- Internal (ID) Grooving & Threading Tools

- Threading Inserts

- Threading Tools

- Boring Bars / Internal (ID) Turning Tools

- External (OD) Turning Tools

- Cermet Turning Inserts

- CBN Turning Inserts

- Haas Notch Grooving & Threading Inserts

- Haas Notch Grooving & Threading Tools

- Micro Turning Tools

- Desktop Lathe Tools

- Indexable Antivibration Boring Bars

-

Lathe WorkholdingLathe Workholding Shop All

-

Package KitsPackage Kits Shop All

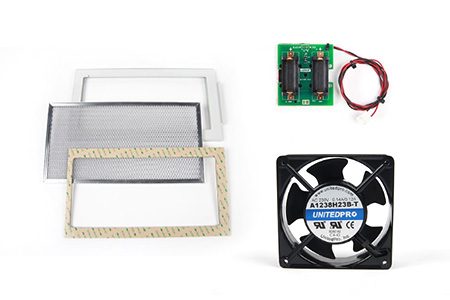

- Chip Clearing Fan Kits

- Cutting Tool Kits

- Indexable End Mill Kits

- Cut-Off Tool Block & Blade Kits

- Drill & Tap Kits

- Indexable Drilling Kits

- Shell Mill Kits

- Chamfer Mill Kits

- Rotary Tool Holder & Tool Chuck Kits

- Lathe Starter Kits

- Workholding Kits

- Rotary Vise Kits

- Vise Kits

- 3-Jaw Chuck Kits for Mills

- Tombstone Kits

- Reduction Sleeve Kits

- Automated Workholding Kits

- 08-1869

- 08-1870

- Measuring & Inspection Kits

- Starter Kits

- Bore Gauge Kits

- Caliper Kits

- Indicator Kits

- Micrometer Kits

-

ER Collets & ChucksER Collets & Chucks Shop All

-

HolemakingHolemaking Shop All

-

ThreadingThreading Shop All

-

BroachingBroaching Shop All

-

TombstonesTombstones Shop All

-

Manual Chucks For MillingManual Chucks For Milling Shop All

-

Deburring & AbrasivesDeburring & Abrasives Shop All

-

Tool Presetter & Heat ShrinkersTool Presetter & Heat Shrinkers Shop All

-

Tool StorageTool Storage Shop All

-

Machine MaintenanceMachine Maintenance Shop All

-

Tooling AccessoriesTooling Accessories Shop All

- Spindle & Toolholder Taper Cleaners

- Haas Shop Lift

- Toolholder Fixtures

- CNC Chip Clearing Fans

- Hammers & Mallets

- Anti-Fatigue Mats

- Layout Tools

- Wrenches

- Magnetic Tools

- Torque Screwdrivers

- Hand Cutting Tools

- Shop Stools

- Lifting Magnets

- Safety Apparel

- Cutting Tool Sharpeners

- Parts Wash-Off Tools & Kits

-

Apparel & AccessoriesApparel & Accessories Shop All

Automation Accessories

Automation Accessories

Shop Support

Shop Support

Mill Toolholding

Mill Toolholding

Mill Cutting Tools

Mill Cutting Tools

Boring Systems

Boring Systems

Mill Workholding

Mill Workholding

Lathe Toolholding

Lathe Toolholding

Lathe Cutting Tools

Lathe Cutting Tools

Lathe Workholding

Lathe Workholding

Package Kits

Package Kits

ER Collets & Chucks

ER Collets & Chucks

Holemaking

Holemaking

Threading

Threading

Broaching

Broaching

Tombstones & Kits

Tombstones & Kits

Manual Chucks For Milling

Manual Chucks For Milling

Deburring & Abrasives

Deburring & Abrasives

Tool Presetter & Heat Shrinkers

Tool Presetter & Heat Shrinkers

Storage & Handling

Storage & Handling

Machine Maintenance

Machine Maintenance

Tooling Accessories

Tooling Accessories

Apparel & Accessories

Apparel & Accessories

Measuring & Inspection

Measuring & Inspection

Winner's Circle

Winner's Circle

Winner's Circle

Winner's Circle

Clearance

Clearance

Today's Hot Deals

Today's Hot Deals

-

Haas Service Parts

Main Menu

- Haas Service Parts

-

Automatic Pallet ChangerAutomatic Pallet Changer Shop All

-

Lathe TurretLathe Turret Shop All

-

Tool ChangerTool Changer Shop All

-

Chip ManagementChip Management Shop All

-

CoolantCoolant Shop All

-

CounterbalanceCounterbalance Shop All

-

Electrical CabinetElectrical Cabinet Shop All

-

EnclosureEnclosure Shop All

-

HydraulicsHydraulics Shop All

-

LubricationLubrication Shop All

-

MaintenanceMaintenance Shop All

-

PendantPendant Shop All

-

ProbingProbing Shop All

-

RotaryRotary Shop All

-

SpindlesSpindles Shop All

-

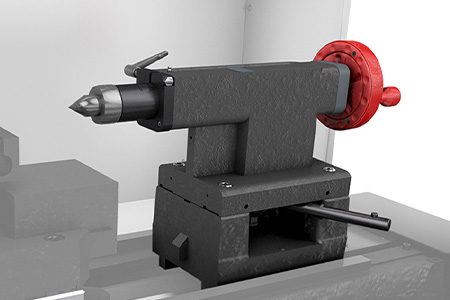

TailstockTailstock Shop All

Automatic Pallet Changer

Automatic Pallet Changer

Lathe Turret

Lathe Turret

Tool Changer

Tool Changer

Chip Management

Chip Management

Coolant

Coolant

Counterbalance

Counterbalance

Electrical Cabinet

Electrical Cabinet

Enclosure

Enclosure

Hydraulics

Hydraulics

Lubrication

Lubrication

Maintenance

Maintenance

Pendant

Pendant

Probing

Probing

Rotary

Rotary

Spindle

Spindle

Tailstock

Tailstock

{{ } }}

{{ } }}

{{ } else { }}

{{ } else { }}