-

기계

Main Menu

-

수직 밀

수직 밀수직 밀 View All

-

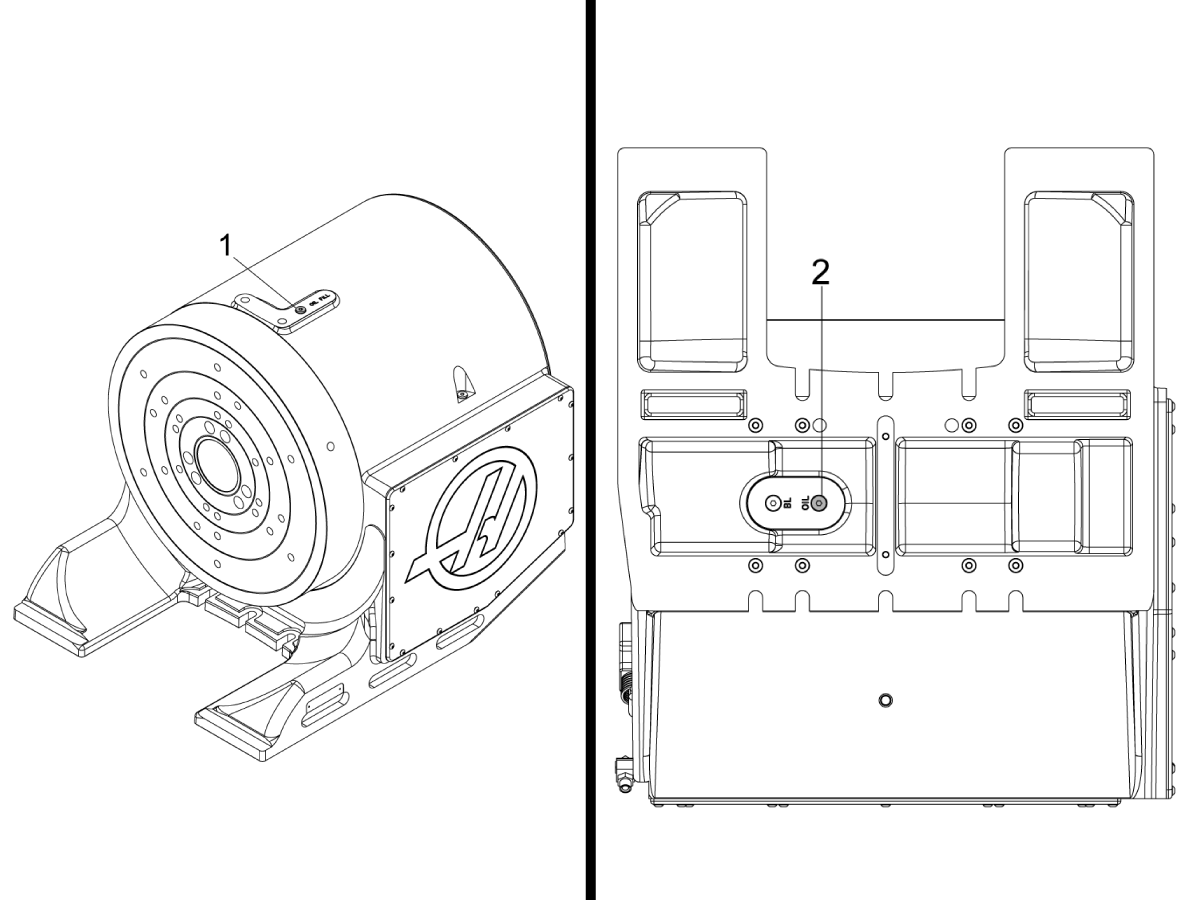

멀티 축 솔루션

멀티 축 솔루션멀티 축 솔루션 View All

-

선반

선반선반 View All

-

수평 밀

수평 밀수평 밀 View All

-

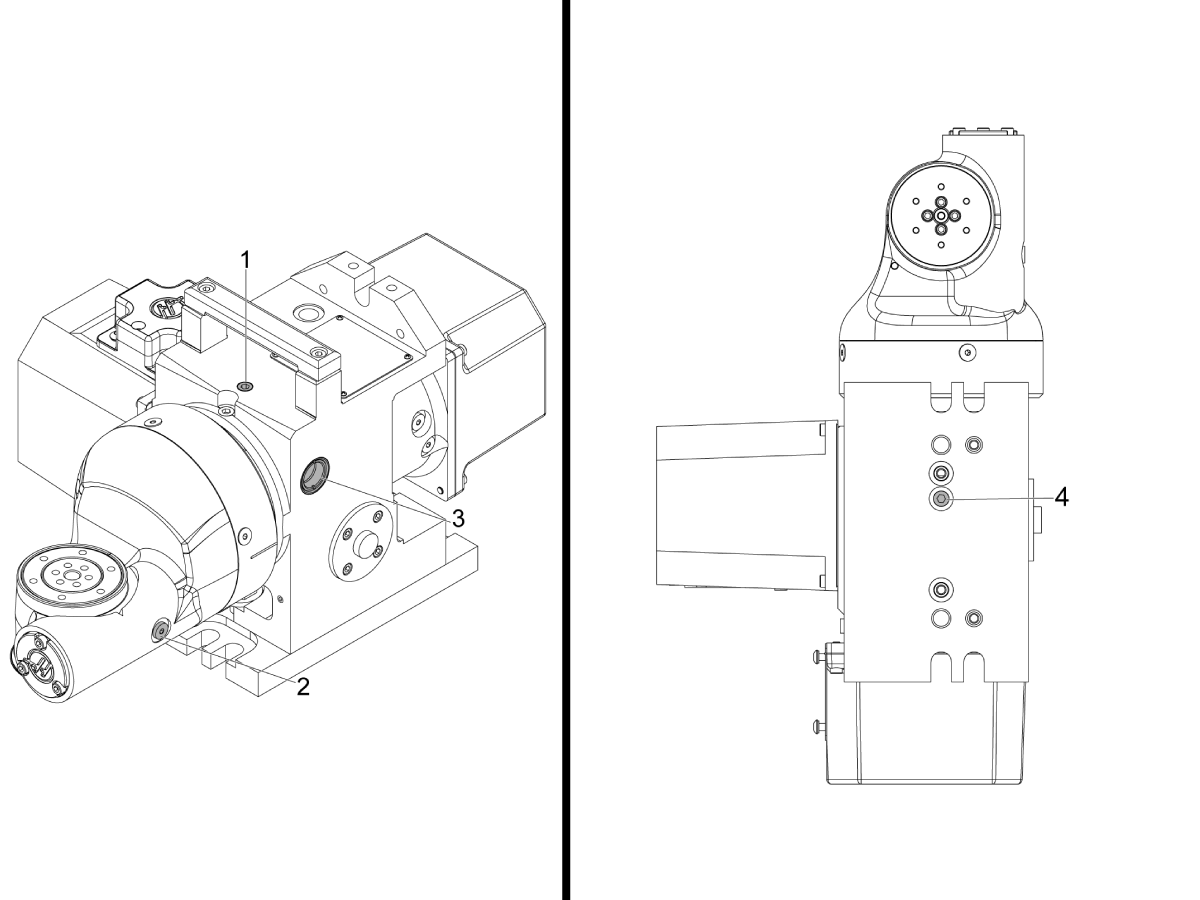

로터리 및 인덱서

로터리 및 인덱서로터리 및 인덱서 View All

-

자동화 시스템

자동화 시스템자동화 시스템 View All

-

데스크톱 기계

데스크톱 기계데스크톱 기계 View All

-

공장 장비

공장 장비공장 장비 View All

-

포켓 기계

포켓 기계포켓 기계 View All

상담을 받고 싶으신가요?Haas Factory Outlet (HFO)은 고객님의 질문에 답변을 드리며 가장 좋은 선택지를 안내해 드립니다.

CONTACT YOUR DISTRIBUTOR > -

수직 밀

-

옵션

Main Menu

-

스핀들

스핀들스핀들 View All

스핀들

스핀들스핀들 View All -

공구 교환장치

공구 교환장치공구 교환장치 View All

공구 교환장치

공구 교환장치공구 교환장치 View All -

4 | 5축

4 | 5축4 | 5축 View All

4 | 5축

4 | 5축4 | 5축 View All -

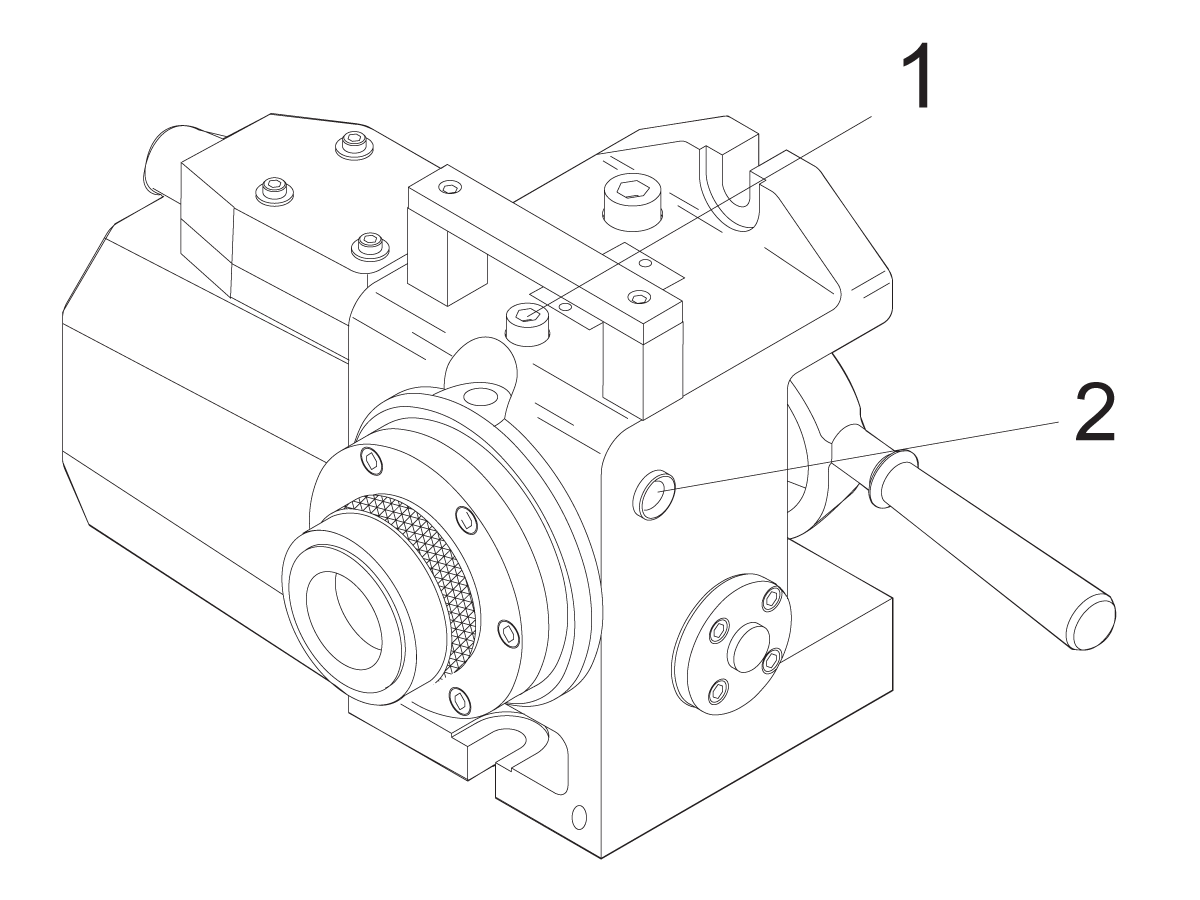

터렛 및 라이브 툴링

터렛 및 라이브 툴링터렛 및 라이브 툴링 View All

터렛 및 라이브 툴링

터렛 및 라이브 툴링터렛 및 라이브 툴링 View All -

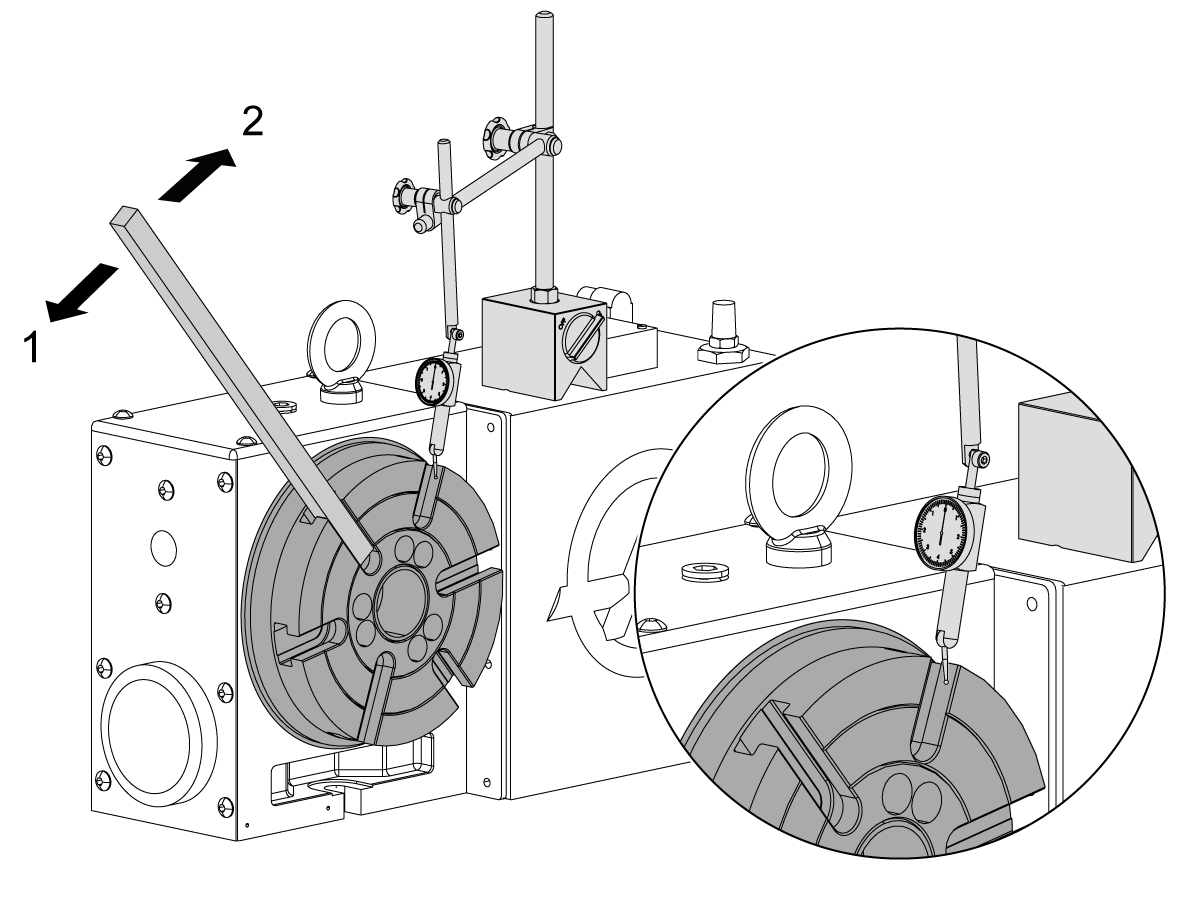

검사

검사검사 View All

검사

검사검사 View All -

칩 및 절삭유 관리

칩 및 절삭유 관리칩 및 절삭유 관리 View All

칩 및 절삭유 관리

칩 및 절삭유 관리칩 및 절삭유 관리 View All -

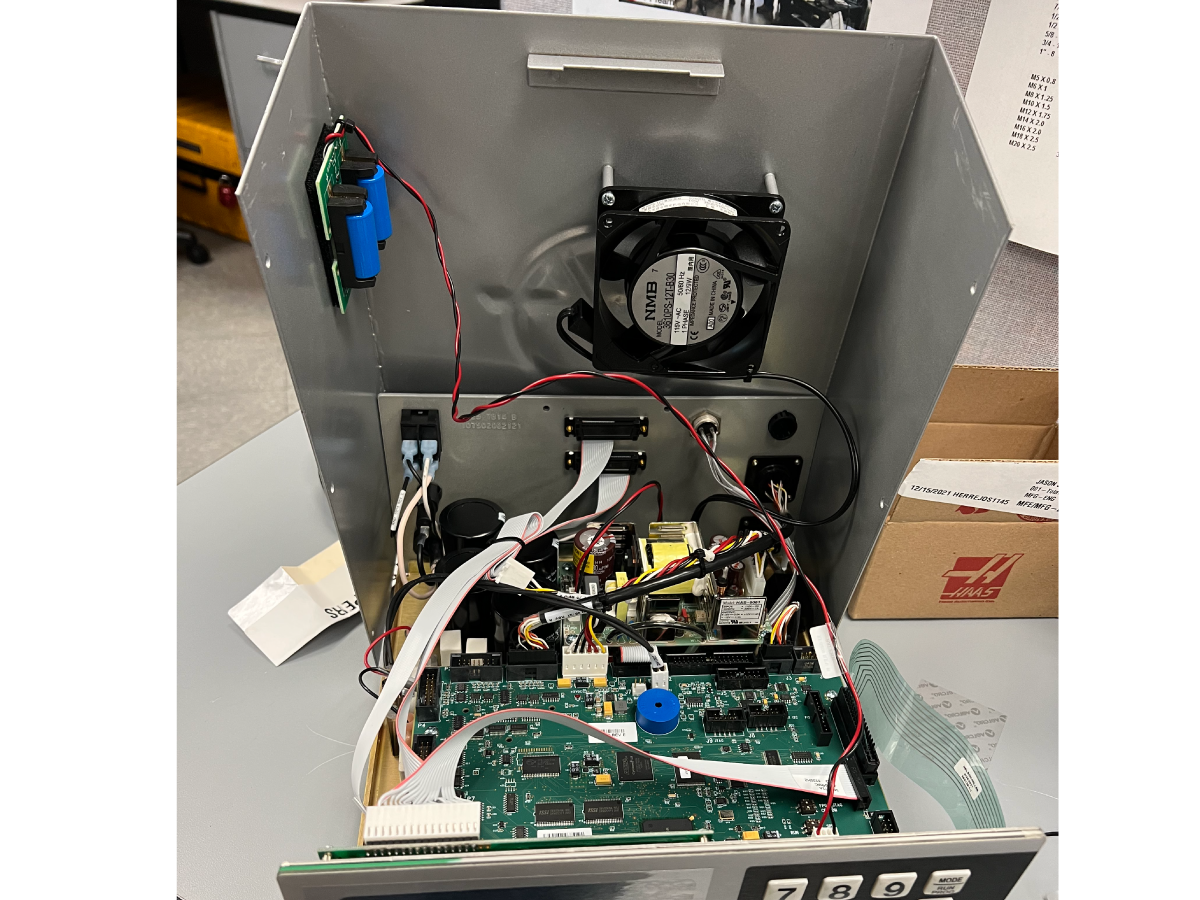

Haas Control

Haas ControlHaas Control View All

Haas Control

Haas ControlHaas Control View All -

제품 선택 사항

제품 선택 사항제품 선택 사항 View All

제품 선택 사항

제품 선택 사항제품 선택 사항 View All -

툴링 및 픽스처링

툴링 및 픽스처링툴링 및 픽스처링 View All

툴링 및 픽스처링

툴링 및 픽스처링툴링 및 픽스처링 View All -

워크홀딩

워크홀딩워크홀딩 View All

워크홀딩

워크홀딩워크홀딩 View All -

5축 솔루션

5축 솔루션5축 솔루션 View All

5축 솔루션

5축 솔루션5축 솔루션 View All -

자동화

자동화자동화 View All

자동화

자동화자동화 View All -

VF-Super-Speed - Super Features Come Standard! | Haas CNC

VF-Super-Speed - Super Features Come Standard! | Haas CNCVF-Super-Speed - Super Features Come Standard! | Haas CNC View All -

UMC-Super-Speed - Super Features Come Standard! | Haas CNC

UMC-Super-Speed - Super Features Come Standard! | Haas CNCUMC-Super-Speed - Super Features Come Standard! | Haas CNC View All -

ST-Y-Axis Standard Features | Haas CNC

ST-Y-Axis Standard Features | Haas CNCST-Y-Axis Standard Features | Haas CNC View All

상담을 받고 싶으신가요?Haas Factory Outlet (HFO)은 고객님의 질문에 답변을 드리며 가장 좋은 선택지를 안내해 드립니다.

CONTACT YOUR DISTRIBUTOR > -

-

Why Haas

Main Menu

Haas의 차이를 알아보세요

-

서비스

Main Menu

- 동영상 Main Menu

.png)

.png)

.png)

.png)

.png)

.png)