Service Update

Troubleshooting Guide

How-To Procedure

Instruction Manual

{{ } }}

{{ } }}

{{ } }}

{{ } }}

A Haas Factory Outlet (HFO) can answer your questions, and walk you through your best options.

CONTACT YOUR DISTRIBUTOR >/VOP-new-way-to-save.gif) Value Option Packages

Value Option Packages

Spindles

Spindles

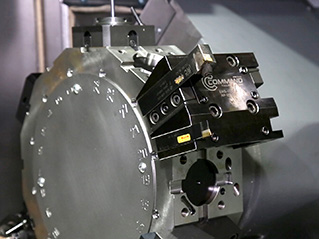

Tool Changers

Tool Changers

4th- | 5th-Axis

4th- | 5th-Axis

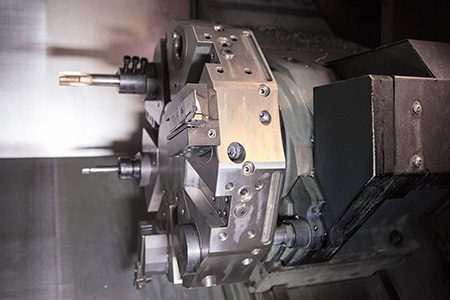

Turrets & Live Tooling

Turrets & Live Tooling

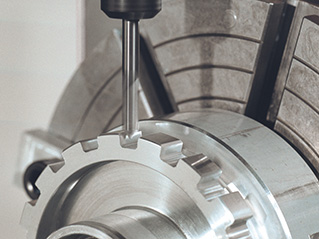

Probing

Probing

Chip & Coolant Management

Chip & Coolant Management

The Haas Control

The Haas Control

Product Options

Product Options

Tooling & Fixturing

Tooling & Fixturing

Workholding

Workholding

5-Axis Solutions

5-Axis Solutions

A Haas Factory Outlet (HFO) can answer your questions, and walk you through your best options.

CONTACT YOUR DISTRIBUTOR >A Haas Factory Outlet (HFO) can answer your questions, and walk you through your best options.

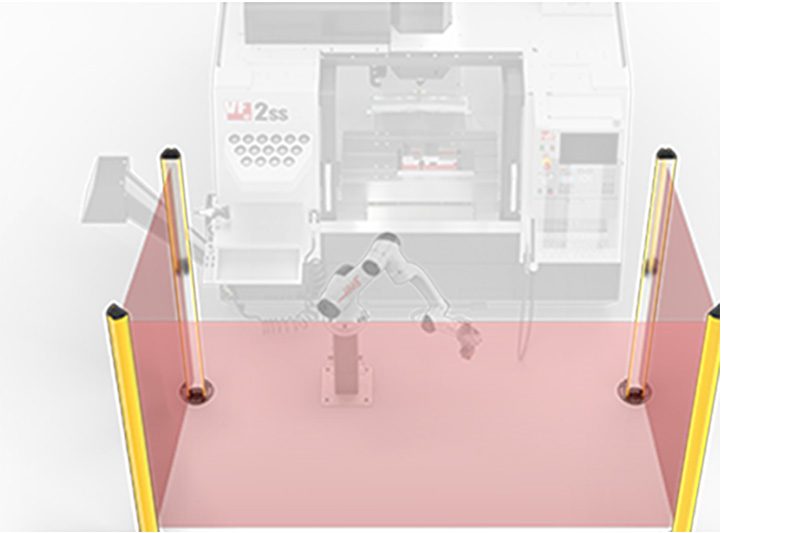

CONTACT YOUR DISTRIBUTOR > Automation Accessories

Automation Accessories

Shop Support

Shop Support

Mill Toolholding

Mill Toolholding

Mill Cutting Tools

Mill Cutting Tools

Boring Systems

Boring Systems

Mill Workholding

Mill Workholding

Lathe Toolholding

Lathe Toolholding

Lathe Cutting Tools

Lathe Cutting Tools

Lathe Workholding

Lathe Workholding

Package Kits

Package Kits

ER Collets & Chucks

ER Collets & Chucks

Holemaking

Holemaking

Threading

Threading

Broaching

Broaching

Tombstones & Kits

Tombstones & Kits

Manual Chucks For Milling

Manual Chucks For Milling

Deburring & Abrasives

Deburring & Abrasives

Tool Presetter & Heat Shrinkers

Tool Presetter & Heat Shrinkers

Storage & Handling

Storage & Handling

Machine Maintenance

Machine Maintenance

Tooling Accessories

Tooling Accessories

Apparel & Accessories

Apparel & Accessories

Measuring & Inspection

Measuring & Inspection

Winner's Circle

Winner's Circle

Winner's Circle

Winner's Circle

Clearance

Clearance

Today's Hot Deals

Today's Hot Deals

Automatic Pallet Changer

Automatic Pallet Changer

Lathe Turret

Lathe Turret

Tool Changer

Tool Changer

Chip Management

Chip Management

Coolant

Coolant

Counterbalance

Counterbalance

Electrical Cabinet

Electrical Cabinet

Enclosure

Enclosure

Hydraulics

Hydraulics

Lubrication

Lubrication

Maintenance

Maintenance

Pendant

Pendant

Probing

Probing

Rotary

Rotary

Spindle

Spindle

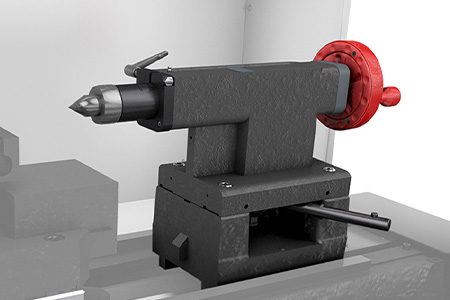

Tailstock

Tailstock

OVERVIEW

SERVICE DOCUMENTS

VIDEOS

AVAILABLE ON THESE MACHINES

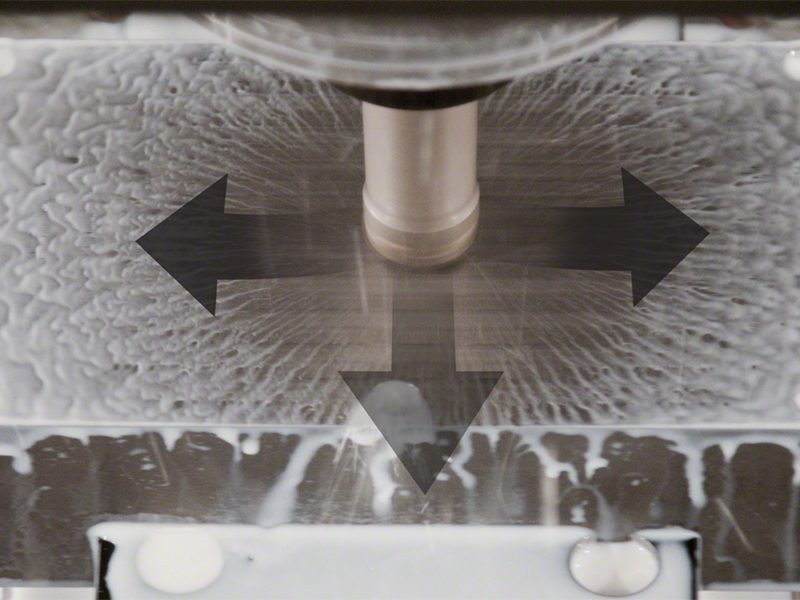

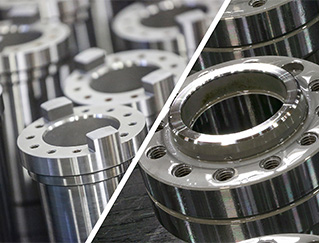

Save time and increase your throughput by running at higher rpm and increased feedrates. Save money by eliminating the need for expensive coolant, and all of its associated costs and time-wasting hassles. Modern tools with special coatings, like titanium aluminum nitride (TiAlN), can run at much higher speeds and feedrates than ever. But those special coatings need to run without coolant (dry machining), and there is a trade-off: You still need to get the chips out of the way or you’ll damage the tool and mar the surface finish. Since these high-speed tools need to run dry, how do you get the chips – and heat – away from the tool? The Haas Through-Tool Air Blast (TAB) option is the perfect solution. TAB supplies high-pressure / high-flow air through the tool, directly to the cutting edge. TAB blasts hot chips away from the tool and cutting zone, allowing you to run 2X the rpm and feedrate you’re used to. Because TAB utilizes the same plumbing that delivers Through-Spindle Coolant, the option requires that you also have a Haas Through-Spindle Coolant (TSC) system, or the TSC Ready option. But that’s great, because you can easily switch between air and coolant through the tool – depending on the application.

NOTE: Requires a Haas Through-Spindle Coolant system, or the TSC Ready option (NGC software version 100.22.000.1000 or later).

Service Update

Troubleshooting Guide

How-To Procedure

Instruction Manual

{{ } }}

{{ } }}

{{ } }}

{{ } }}

Re-cutting chips during dry machining is bad! Blast them out of the way with the Haas TAB option.

If you would like more information about how a new Haas machine can bring your products to life, please share your contact information.

All prices and specifications subject to change without notice. Freight, rigging, state & local taxes, vendor installation charges, and dealer installed accessories are not included. Not responsible for misprints or typographical errors. Machines shown with optional equipment. Actual product appearance may differ.

Recently Viewed Items

You Have No Recently Viewed Items Yet

美元价格不包括关税、报关费用、保险费、增值税及运费。

USD prices DO NOT include customs duty, customs fees, insurance, VAT, or freight.

人民币价格包含关税、报关费用、货运保险和增值税, 但不包括运费。

CNY prices include customs duty, customs fees, insurance, and VAT. DOES NOT include freight.

This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer. No other mandatory costs can be added to the delivery of a Haas CNC Product.

KEEP UP WITH THE LATEST HAAS TIPS AND TECHNOLOGY...

HAAS TOOLING ACCEPTS THE FOLLOWING:

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

2800 Sturgis Rd., Oxnard, CA 93030

Toll Free: (888) 817-4446 / Fax: 805-278-8554