Troubleshooting Guide

Videos

How-To Procedure

Instruction Manual

{{ } }}

{{ } }}

{{ } }}

{{ } }}

Vertical Mills

Vertical Mills

Multi-Axis Solutions

Multi-Axis Solutions

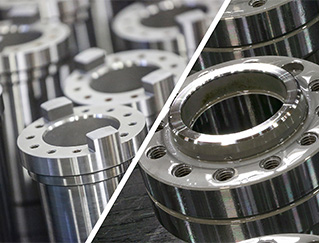

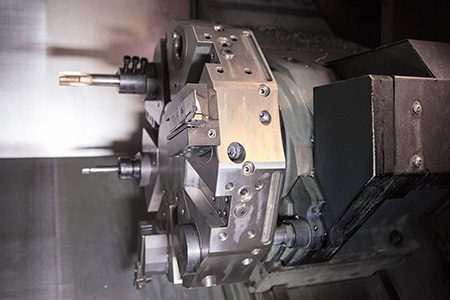

Lathes

Lathes

Horizontal Mills

Horizontal Mills

Rotaries & Indexers

Rotaries & Indexers

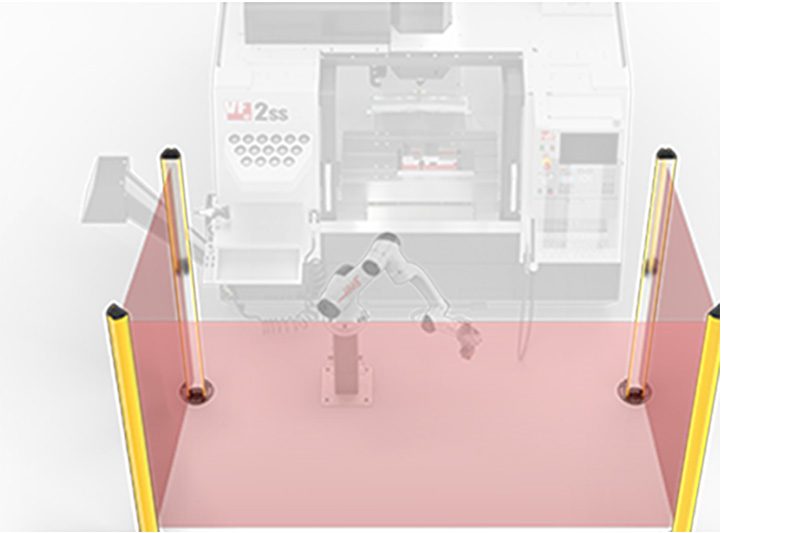

Automation Systems

Automation Systems

Desktop Machines

Desktop Machines

Shop Equipment

Shop Equipment

A Haas Factory Outlet (HFO) can answer your questions, and walk you through your best options.

CONTACT YOUR DISTRIBUTOR >/VOP-new-way-to-save.gif) Value Option Packages

Value Option Packages

Spindles

Spindles

Tool Changers

Tool Changers

4th- | 5th-Axis

4th- | 5th-Axis

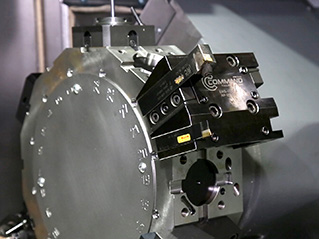

Turrets & Live Tooling

Turrets & Live Tooling

Probing

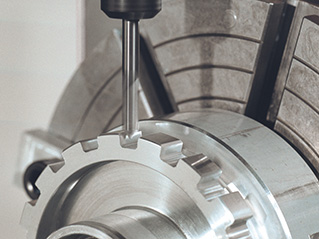

Probing

Chip & Coolant Management

Chip & Coolant Management

The Haas Control

The Haas Control

Product Options

Product Options

Tooling & Fixturing

Tooling & Fixturing

Workholding

Workholding

5-Axis Solutions

5-Axis Solutions

A Haas Factory Outlet (HFO) can answer your questions, and walk you through your best options.

CONTACT YOUR DISTRIBUTOR >A Haas Factory Outlet (HFO) can answer your questions, and walk you through your best options.

CONTACT YOUR DISTRIBUTOR > Automation Accessories

Automation Accessories

Shop Support

Shop Support

Mill Toolholding

Mill Toolholding

Mill Cutting Tools

Mill Cutting Tools

Boring Systems

Boring Systems

Mill Workholding

Mill Workholding

Lathe Toolholding

Lathe Toolholding

Lathe Cutting Tools

Lathe Cutting Tools

Lathe Workholding

Lathe Workholding

Package Kits

Package Kits

ER Collets & Chucks

ER Collets & Chucks

Holemaking

Holemaking

Threading

Threading

Broaching

Broaching

Tombstones & Kits

Tombstones & Kits

Manual Chucks For Milling

Manual Chucks For Milling

Deburring & Abrasives

Deburring & Abrasives

Tool Presetter & Heat Shrinkers

Tool Presetter & Heat Shrinkers

Storage & Handling

Storage & Handling

Machine Maintenance

Machine Maintenance

Tooling Accessories

Tooling Accessories

Apparel & Accessories

Apparel & Accessories

Measuring & Inspection

Measuring & Inspection

Winner's Circle

Winner's Circle

Winner's Circle

Winner's Circle

Clearance

Clearance

Today's Hot Deals

Today's Hot Deals

Automatic Pallet Changer

Automatic Pallet Changer

Lathe Turret

Lathe Turret

Tool Changer

Tool Changer

Chip Management

Chip Management

Coolant

Coolant

Counterbalance

Counterbalance

Electrical Cabinet

Electrical Cabinet

Enclosure

Enclosure

Hydraulics

Hydraulics

Lubrication

Lubrication

Maintenance

Maintenance

Pendant

Pendant

Probing

Probing

Rotary

Rotary

Spindle

Spindle

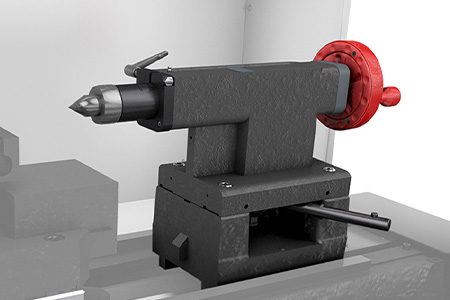

Tailstock

Tailstock

Set up your Haas mill up to 5 times faster using the Haas Wireless Intuitive Probing System (WIPS). WIPS is a complete probing package that includes the spindle probe, tool setting probe, and optical machine interface, along with powerful software that guides the operator through the job setup process with intuitive, easy-to-use templates.

OVERVIEW

SERVICE DOCUMENTS

VIDEOS

AVAILABLE ON THESE MACHINES

WIPS allows you to quickly and easily define work offset coordinates, set tool length offsets, and perform in-process inspection, for both part inspection and tool breakage detection. WIPS is the single best productivity improvement you can add to your Haas mill.

Troubleshooting Guide

Videos

How-To Procedure

Instruction Manual

{{ } }}

{{ } }}

{{ } }}

{{ } }}

Everyone takes for granted that their probing system is giving them reliable, accurate values for their work and tool offsets. But have you ever wondered how those work and tool offsets are actually calculated? Well wonder no more as Mark breaks down the mechanics and math behind where those numbers come from.

Anyone who has run a machine knows how long it takes to set your work offsets. What if you could do it in a fraction of the time? It turns out you can, and it’s easier than you think!

Order the Wireless Intuitive Probing System on any Haas 50-taper VMC, and we’ll include our 50-taper tool load stand for free, allowing you to load heavy and oversized tools quickly, easily, and safely.

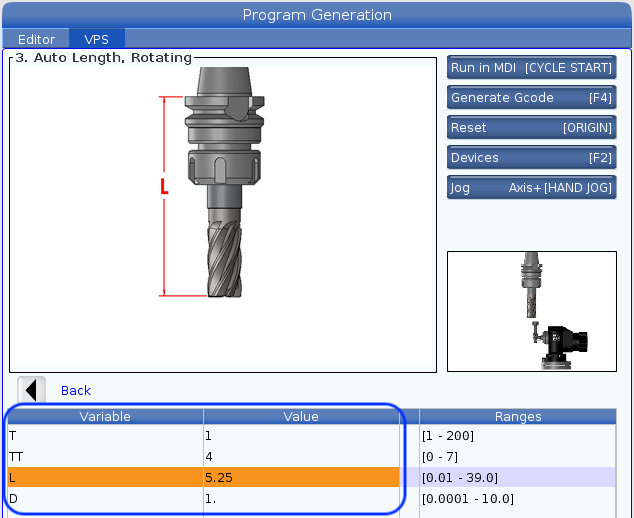

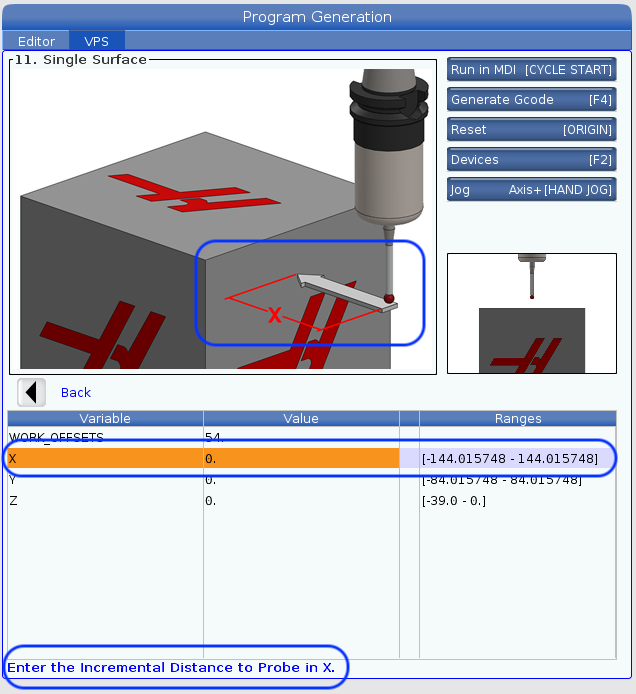

The Haas Wireless Intuitive Probing System (WIPS) guides the operator through the job set-up process with easy-to-use templates. The templates help reduce setup time by allowing the operator to multitask while the automatic probing routines are running. WIPS can also ensure that parts and tools are maintained within tolerance throughout the production process, by using the available wear and break-detection routines. WIPS has the ability to define work offset coordinates, set tool length offsets, and perform in-process inspection within the program.

WIPS includes:

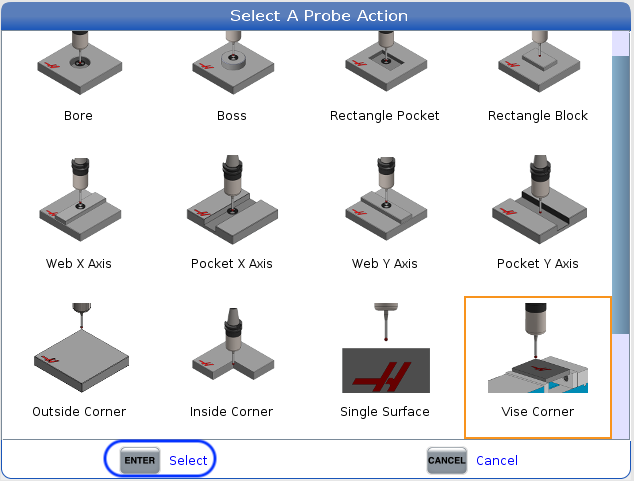

Easy-to-use work offset cycles

* Advanced programming methods allow in-process part inspection

Depending on the machine configuration, fixture, or part height, a tool probe riser may be necessary.

Haas provides two options to raise the tool probe from the table to avoid any interference with the workholding or workpiece:

You can order these risers on Parts.HaasCNC.com using part numbers PRB-EC3 or PRB-EC8.

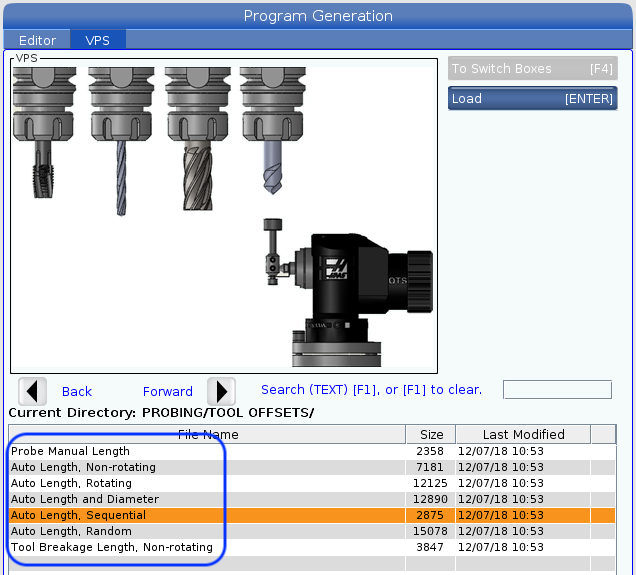

The probes are operated by small programs called probe cycles, which are designed to carry out specific tasks. Each task requires data input, based on the workpiece and the task. Haas Automation provides Visual Programming System (VPS) templates to simplify data entry for calibrating the probe system, setting offsets, and finding the location of rotary tables and tool loaders.

But, the probe system is capable of so much more. With the probe programming manual and a little bit of programming knowledge, you can command the WIPS system to perform these advanced functions:

WARNING - www.P65Warnings.ca.gov

{{=itemTitle}}

Part #: {{=itemSku}}

RETAIL PRICE:

{{ }); }} {{if (itemAllDiscountPrices.length) {}} {{_.forEach(itemAllDiscountPrices, function(dPrice){ }}{{=dPrice.amount}}

WARNING - www.P65Warnings.ca.gov

{{=itemTitle}}

Part #: {{=itemSku}}

{{ } }}RETAIL PRICE:

{{ }); }} {{if (itemAllDiscountPrices.length) {}} {{_.forEach(itemAllDiscountPrices, function(dPrice){ }}{{=dPrice.amount}}

Success! {{=qty}} item(s) added to cart!

Subtotal: {{=sub}}

If you would like more information about how a new Haas machine can bring your products to life, please share your contact information.

All prices and specifications subject to change without notice. Freight, rigging, state & local taxes, vendor installation charges, and dealer installed accessories are not included. Not responsible for misprints or typographical errors. Machines shown with optional equipment. Actual product appearance may differ.

Recently Viewed Items

You Have No Recently Viewed Items Yet

美元价格不包括关税、报关费用、保险费、增值税及运费。

USD prices DO NOT include customs duty, customs fees, insurance, VAT, or freight.

人民币价格包含关税、报关费用、货运保险和增值税, 但不包括运费。

CNY prices include customs duty, customs fees, insurance, and VAT. DOES NOT include freight.

This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer. No other mandatory costs can be added to the delivery of a Haas CNC Product.

KEEP UP WITH THE LATEST HAAS TIPS AND TECHNOLOGY...

HAAS TOOLING ACCEPTS THE FOLLOWING:

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

2800 Sturgis Rd., Oxnard, CA 93030

Toll Free: (888) 817-4446 / Fax: 805-278-8554